99Panhard

Stainless

- Joined

- Feb 22, 2006

- Location

- Smithfield, Rhode Island

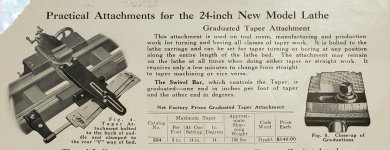

My Sidney lathe, a 14-inch cone head, had a taper attachment. When I bought it (at a printing auction about 40 years ago) I got part of the TA. I'm guessing the rest of it was there but I knew so little about them at the time that I didn't see it and left without it. Now I have a project that may call for a fairly long internal taper and would like to get it working. I'm looking for:

Another one...

or parts for this one...

or photos of what it looked like on the machine so I can try to make the missing parts. If it involves elaborate castings, that may be an issue. If I understood how it worked it's possible I could fit something else.

Tomorrow, when I'm in the shop, I'll take some pictures of what I do have and post them. As it is, I don't even know how it worked although it looks as if you have to remove the cross feed screw and attach the saddle to the TA...is that normal? I've only had one in the past and don't think I ever used it. Ironically enough, I also have a partial TA on my tie-bar Hendey but that one is apart and some way from being useful.

Another one...

or parts for this one...

or photos of what it looked like on the machine so I can try to make the missing parts. If it involves elaborate castings, that may be an issue. If I understood how it worked it's possible I could fit something else.

Tomorrow, when I'm in the shop, I'll take some pictures of what I do have and post them. As it is, I don't even know how it worked although it looks as if you have to remove the cross feed screw and attach the saddle to the TA...is that normal? I've only had one in the past and don't think I ever used it. Ironically enough, I also have a partial TA on my tie-bar Hendey but that one is apart and some way from being useful.