Gents, many thanks for your contributions. I suspect that “technocrat” is correct and that the lathe is from Johann Weisser. This assessment is based on the following observations.

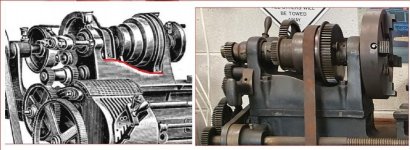

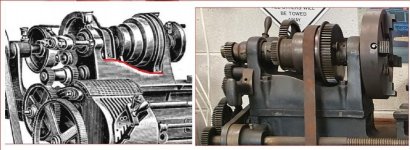

1. The images on the left are from the Johann Weisser pages at Lathes.co.uk. I found an image of one lathe that has an identical treadle arrangement.

2. The shape of the legs also appears to be the same.

3. The casting that holds the spindle and driven pulleys is the same shape as mine.

4. I’ve only managed to find identical steady rests in 2 Johann Weisser images.

5. The tool holding system appears to be the same.

6. The step down in the bed under the gap in the bed appears to be the same.

7. The change gears appear to be the same design.

Having said that, evidence to the contrary is the fact that there is no Johann Weisser label on it. Other Johann Weisser lathes appear to be labelled as such.

The Lathes.co.uk site also reveals the following:

“Oscar Ehrlich was a well known, long-established and prolific manufacturer of lathes with premises at Chemnitz, in Germany. Although the Company exported widely, it appears to have been common for them to leave off any identifying marks from their machines and instead market them through distributors”. So is it an Oscar Ehrlich?

The appearance and font used on the change gear table of an Oscar Ehrlich lathe in an image from Lathes.co.uk appears to be the same as mine. However it has an Oscar Ehrlich logo on it and mine doesn’t.

I thought I was on to an answer recently when I saw a local on-line advertisement for a lathe with the same style of tail stock. I approached the seller about the brand but he had also been unable to find any identifying marks.

So, my best guess is Johann Weisser, but I’d be happy to be shown if I’ve got it wrong.