I have had this mill for two or three years. The head is a Bridgeport C head with stationary quill. It's a mid 1930's model, prior to the formation of Bridgeport Machines Inc. I have done all my research on the head because I had a serial number and manufacturer on the nameplate to look up. I was always curious about the knee because it has no nameplate or any manufacturer's name in the casting. I didn't know anything about milling machines before I got this, so my lack of knowledge kept me from seeing one obvious detail. I finally realized that none of the modern knee bases have an x-axis travel for the head on the base because sliding quills came out shortly after my head was made. I always thought my base was some more modern vintage import. The shape of my base is very unique, though. As is one other thing, the knee screw and its housing.

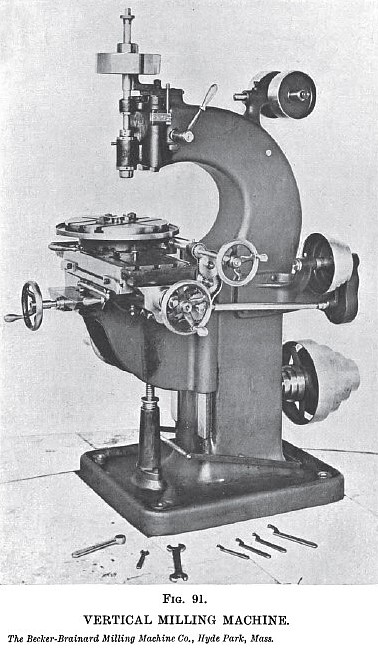

So I started looking at old machines and saw a picture of a Becker vertical machine. Sure enough, it has an identical shape, exposed knee screw and its lower housing. I haven't seen this style and shape anywhere else. So I started looking more closely at my machine. What I originally thought were DRO mounts, look exactly like like the old pulley and belt mounts.

A few other things I've noticed is that the dials don't match. I thought maybe the saddle was modern and stuck on an old base, but the dial indicators match on both the Y-axis, which is part of the base casting and the X-axis which is on the saddle. The only difference is the dial. So I assume the saddle is original and the dials might have been changed out on the Y-axis. Also, many of the Becker machines I've seen have a different shape base at the bottom. The No. 2 has the same sloped downward style as mine, but my machine doesn't look like a No. 2. Later models have a raised lip around the edge of the base, presumably for catching oil and cooling fluids, while mine has a rounded, sloping edge on the bottom of the base. My machine has what looks just like the Becker door where the model name would be. Unfortunately the door is missing. I am still left wondering why I don't see any manufacturer name in the casting.

So all that's left is to post the pictures and see what you guys think. Any information would be greatly appreciated. Sorry for the lousy photos, the mill is crammed in the corner of the garage and hard to get to.

So I started looking at old machines and saw a picture of a Becker vertical machine. Sure enough, it has an identical shape, exposed knee screw and its lower housing. I haven't seen this style and shape anywhere else. So I started looking more closely at my machine. What I originally thought were DRO mounts, look exactly like like the old pulley and belt mounts.

A few other things I've noticed is that the dials don't match. I thought maybe the saddle was modern and stuck on an old base, but the dial indicators match on both the Y-axis, which is part of the base casting and the X-axis which is on the saddle. The only difference is the dial. So I assume the saddle is original and the dials might have been changed out on the Y-axis. Also, many of the Becker machines I've seen have a different shape base at the bottom. The No. 2 has the same sloped downward style as mine, but my machine doesn't look like a No. 2. Later models have a raised lip around the edge of the base, presumably for catching oil and cooling fluids, while mine has a rounded, sloping edge on the bottom of the base. My machine has what looks just like the Becker door where the model name would be. Unfortunately the door is missing. I am still left wondering why I don't see any manufacturer name in the casting.

So all that's left is to post the pictures and see what you guys think. Any information would be greatly appreciated. Sorry for the lousy photos, the mill is crammed in the corner of the garage and hard to get to.