Froneck

Titanium

- Joined

- Dec 4, 2010

- Location

- McClure, PA 17059

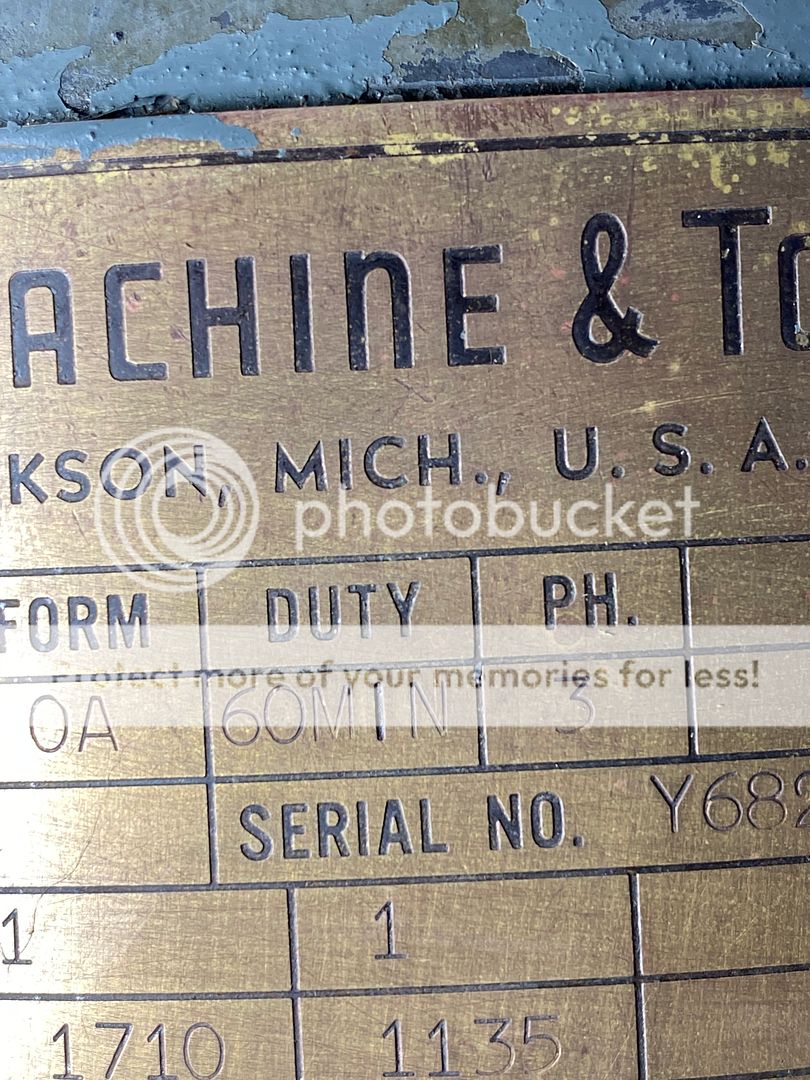

What seems to be a nice Index Model 55 mill is available at HGR Surplus item # 1119-155-0029. Has table and Quill power feed. Probably Morse or B&S tapered spindle. Round arm and not variable speed. I had one and think it will make a good entry level mill for someone wanting a mill. Current price is $459 but it will soon be marked down again plus there will be another up-coming sale, -20% on machinery ($367)If you keep an eye on it I'm sure it will eventually drop to about $150 if no one buys it.

Do I want it? If I had room I'd buy it but I need a shoe horn to get in my shop now plus I just purchased 2 turret lathes and 2 engine lathes from HGR!

Do I want it? If I had room I'd buy it but I need a shoe horn to get in my shop now plus I just purchased 2 turret lathes and 2 engine lathes from HGR!