Hi all,

First, ditto on the deburring ad all the way.

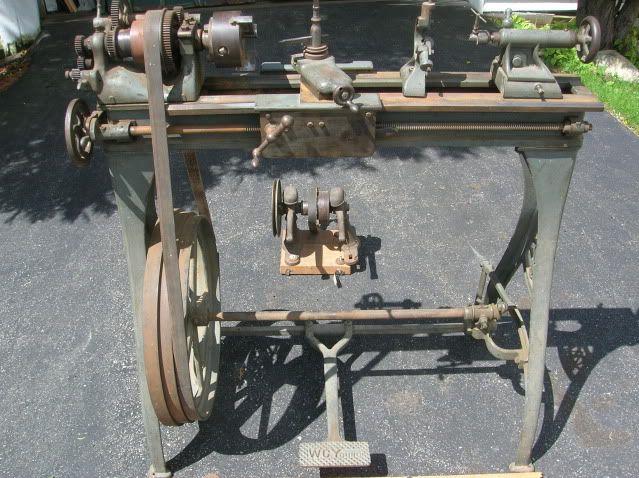

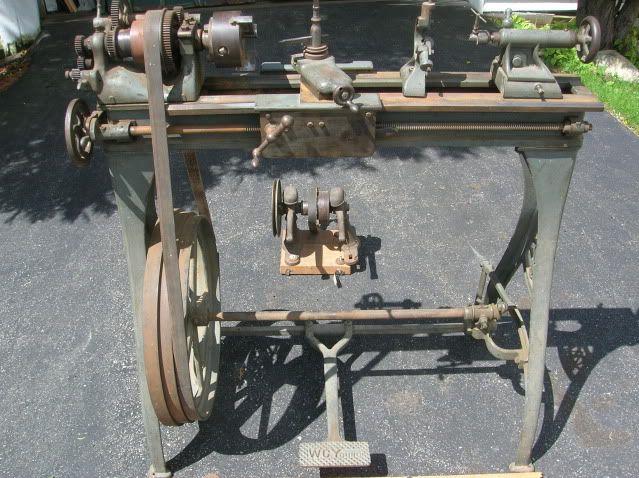

The lathe is a "doll baby" as we say down south and yoiu did just right on cleaning her. Hard to put the patina back in once you take it out. Where there is at least some of the original finsih, faded or not, I think it should be left.

One the number of treadle lathes, Barnes was by far the biggest mfg and started very early. Way back in about 1878, they were marketing a metal lathe. Also as pointed out, they made them in a number of sizes.. 4, 4 1/2, 5, 5 1/2, 6 & 13 with them getting bigger as the numbers went up. No telling how many they made but in the many thousand overall I would say.

Barnes did have a significant name recognition given all the different types of foot powered machinery they made and yes, a large dealer network. Interesting to see the dealers listed in some of their catalogs.

They did stamp a serial number on them so we could probably do some investigating and get some idea.

Next you will find Seneca Falls but they are a long distance behind Barnes. That probably goes for all of the SF foot powered machinery including the scroll saws, table saws, etc. In my opinion, I think SF built a better, more robust machine and they put a serial number at least on their metal lathes. I had a complete 12 in one that as I remember had a 7800 something number. I do think that they sold a number that were line shaft driven and they probably just used the same serial numbering sequence so it might be hard to really establish a good estimate.

After SF, the other manufacturers I have in my collection are Young, Shephard, Shephard Tool Co, Baldwin, Reed, Sebastian May and Spencer in screw cutting versions. There are not many of these lesser known mfg out there.

The Young I have is a hand or speed lathe. It looks like the one you have but does not have the traditional lead screw. The compound slides up and down the metal bed and can be locked in at any place. The tool post can then be moved using the traditional screw adjustment. These hand or speed lathes also had a wood turing attachment and I think were targeted to somebody that did not want to pay the full price for a screw cutting lathe but did want metal cutting ability.

My Young has a serial number stamped in a small slightly raised round area on the right end of the bed. It is F. F. 2347 Not sure what the letters meant unless it was a model designation. I will try and get some pictures and post them here.

My website at

Foot Powered Machinery is still very much a work in process with very little content. The mfg list is there and one day I want to get a lot of pictures, info, catalog cuts, et.

Would you mind if I used some of your pictuures of the Youndg lathe on my site in that section?

Those cutters are solid and might well have been forged. I have a 1918 Barens lathe catalog and that is all they offered at the time. They came in different sizes for differnt size lathes.

Don't know when the holder with individual cutters came into play. When you sharpened these too much, you were effective out of tooling instead of buying just a new cutter insert.

Hope some of this helps..

I just love foot powered machinery!!

Thanks Ed

the