This is in responce to T. Nguyen Binh's questions about the Hardinge. There is a separate Hardinge forum and this is the Deckel, Aciera etc. site so I don't want to beat this subject to death in this forum.

The best summary of what makes the Hardinge special is Tony's article at

WWW.lathes.co.uk. Read this section and you will get a good overvue.

My personal experience stems from the fact that for the last 10 years of visiting machinery repair and rebuilding shops in Oregon and California, everyone of these shops with no exceptions had a Hardinge lathe that was not for sell and was their working lathe used to make parts for the lathes that they were rebuilding. They would not even discuss selling their Hardinge. You have to admit that if machinery rebuild shops revor this lathe there must be some substance to it.

As far as tooling goes, we are talking the basics ie chucks, collets, live centers, follow rests etc. but i don't need to remind you that even the basic tooling is hard to find for the Deckel, Aciera group which means buy the machine and spend a year trying to get up and running.

Now, let me clear the air here by reemphasizing that I will eventually obtain all I need for my FP-1. I am confident of that. The more I work with this machine the more in awe of it I am.

Over the years I have taken a number of courses at our local community college in milling and lathe work where series 1 Bridgeports are the rule. They are great mills but they don't have the universal capacity of the Deckel, are larger and despite what Sean says and my limited experience with the Deckel, the Deckel seems to be able to cut as agressively as the Bridgeport. Yes, there are other milling attachments that you can buy for the Bridgeport but they are work arounds and my teacher at the community college who was a tool and diemaker for twenty years says it is "too much trouble to mount the horizontal arbor, slotting head etc,, on the Bridgeport" not so with the Deckel.

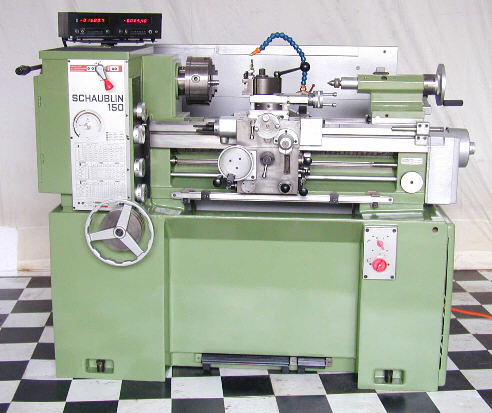

I have to admit that I have heard good things about the Schaublin but have no experience with it. The American made Rivett is new to me but it is listed in lathe archive and my interest has been piqued so I'll read about it...but i don't need and can't afford another lathe (not that I wouldn't like to have one... now if I could just be Bill Gates for a day and have his bank account).

Interesting to read D. Thomas's experience with the missed bargain on the Schaublin. I have had a couple of those type of experiencies and still grieve over them. I remember finding a Southbend 9A that had been mothballed for 20 years and the hand scraping on the ways was pristine and what a bargain ! It took me a couple a months to realize how stupid i was for passing it up.

The only time I can recall really siezing that type of deal was a 0 to 21/2 inch snap gage from starrett with stand that sells for $1250.00. Found it in a local pawn shop, bought it for $68.00 and took it to a local calibration shop that said it was perfect. You should have seen the look on the precision instrument guy's face when I told him what I payed for it. I keep hoping it will happen again.

best regards

noahjlb

)) : this is the best machining site I`ve ever seen!

)) : this is the best machining site I`ve ever seen!