Luke

Hot Rolled

- Joined

- Aug 23, 2003

- Location

- Nevada,Iowa

This has been my weekend project for about 9 months and its coming into full gestation. I will be building up a crown for the top of this and only want to do this once.

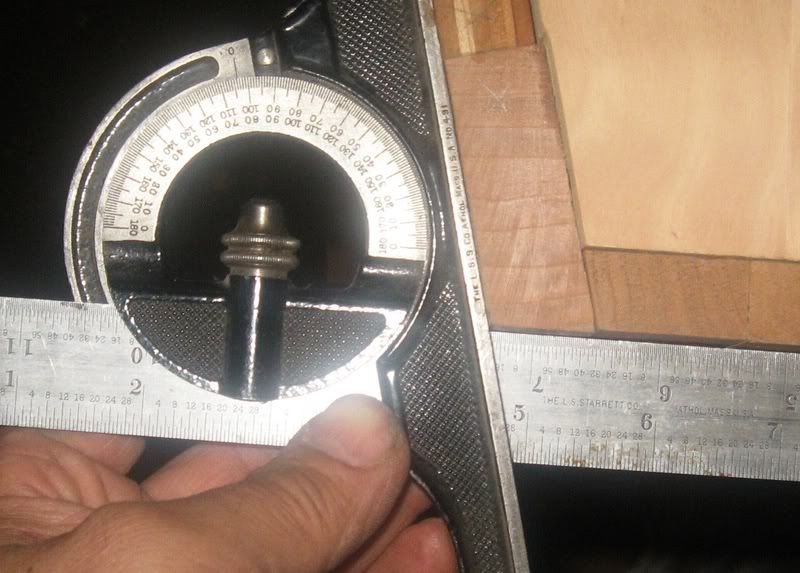

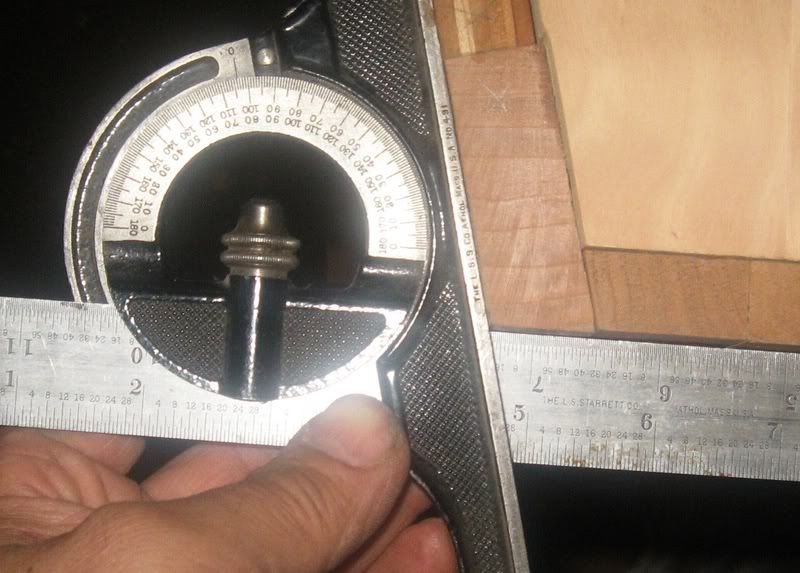

From this measurement it is 104 degrees. Will my cut simply be 52 degrees for each piece,or? This will not be a compound cut as the molding will fit tight to the face.

This will not be a compound cut as the molding will fit tight to the face.

Its taken me 9 months to get this far, and with all the final sanding and finishing I don't expect this to be done before September.

Thanks for the help!

From this measurement it is 104 degrees. Will my cut simply be 52 degrees for each piece,or?

This will not be a compound cut as the molding will fit tight to the face.

This will not be a compound cut as the molding will fit tight to the face.

Its taken me 9 months to get this far, and with all the final sanding and finishing I don't expect this to be done before September.

Thanks for the help!