Hey! I just traded some other equipment for a Bridgeport 2J mill. I've always wanted one.

This one works great in high speed but in low speed in makes kind of a light growling almost like a bad bearing and has low torque. It will actually pull quite a bit harder in high speed at 500 RPM than it will at 100 RPM in low speed. When it stalls in low speed it feels like a belt slipping. The motor keeps spinning but the spindle stops turning. Let up a little on down pressure and it will take off again.

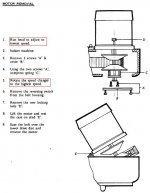

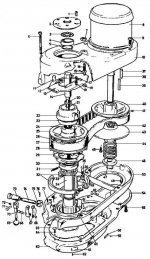

Does anyone have any ideas on what might cause this? I've looked at the diagrams enough to see there are two belts in the head. What does the timing belt do? Does the timing belt run the low speed?

This one works great in high speed but in low speed in makes kind of a light growling almost like a bad bearing and has low torque. It will actually pull quite a bit harder in high speed at 500 RPM than it will at 100 RPM in low speed. When it stalls in low speed it feels like a belt slipping. The motor keeps spinning but the spindle stops turning. Let up a little on down pressure and it will take off again.

Does anyone have any ideas on what might cause this? I've looked at the diagrams enough to see there are two belts in the head. What does the timing belt do? Does the timing belt run the low speed?