Hi guys, I have a Bridgeport VMC 800 22 that has some issues with tool run out. The tool taper in the spindle runs true, but with a tool fitted there is runout. I blued up the inside of the taper and you can see that there is partial contact top and bottom, 180' apart, as if the holder is not being pulled up true.

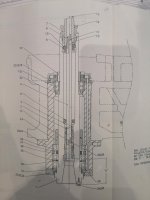

I wanted to check the drawbar for broken springs or worn ball bearings, but from the drawing I'm not sure how it comes out! It looks like there is a nut at the top that could be removed with a hooked pin spanner (once the drawbar actuator has been removed), but the drawings describe it as a spindle end cap.

Is it a case of removing this nut, and then pushing the drawbar up from the bottom, and retrieving the washers with a magnet?

I wanted to check the drawbar for broken springs or worn ball bearings, but from the drawing I'm not sure how it comes out! It looks like there is a nut at the top that could be removed with a hooked pin spanner (once the drawbar actuator has been removed), but the drawings describe it as a spindle end cap.

Is it a case of removing this nut, and then pushing the drawbar up from the bottom, and retrieving the washers with a magnet?