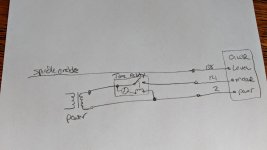

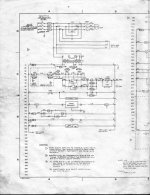

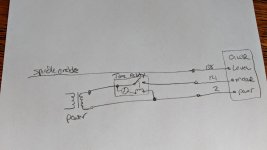

I converted an old boss5 to mach3 and it has a powered oiler. Looking at the old Bridgeport schematic below, it looks like the spindle will be killed if the oiler runs out, which is fine, but I can't really understand from the diagram how the oiler is activated with the indichron. The other photos are of the capacitor on the contact terminal block and old indichron timing device ( https://datasheet.octopart.com/120PC12625-Curtis-Industries-datasheet-27869806.pdf ) Looks to me like the capacitor is dead (has a crack and reads open), and I want to eliminate the indichron in favor of a timer relay. My plan is to leave wire 138 as is so it will still kill the spindle if oil runs out and wire as shown, but I don't know how long to run the oiler motor or how often- any advice would be appreciated. I'm not super familiar with these powered oilers but it looks like its driven by a cam to raise the pump handle so I would only need it to run for one revolution then every x hours, but if the machine is only run for x-1 hours many times it could conceivably never oil so I need a strategy there