Stronghold

Aluminum

- Joined

- Jan 5, 2015

- Location

- Jefferson City, MO

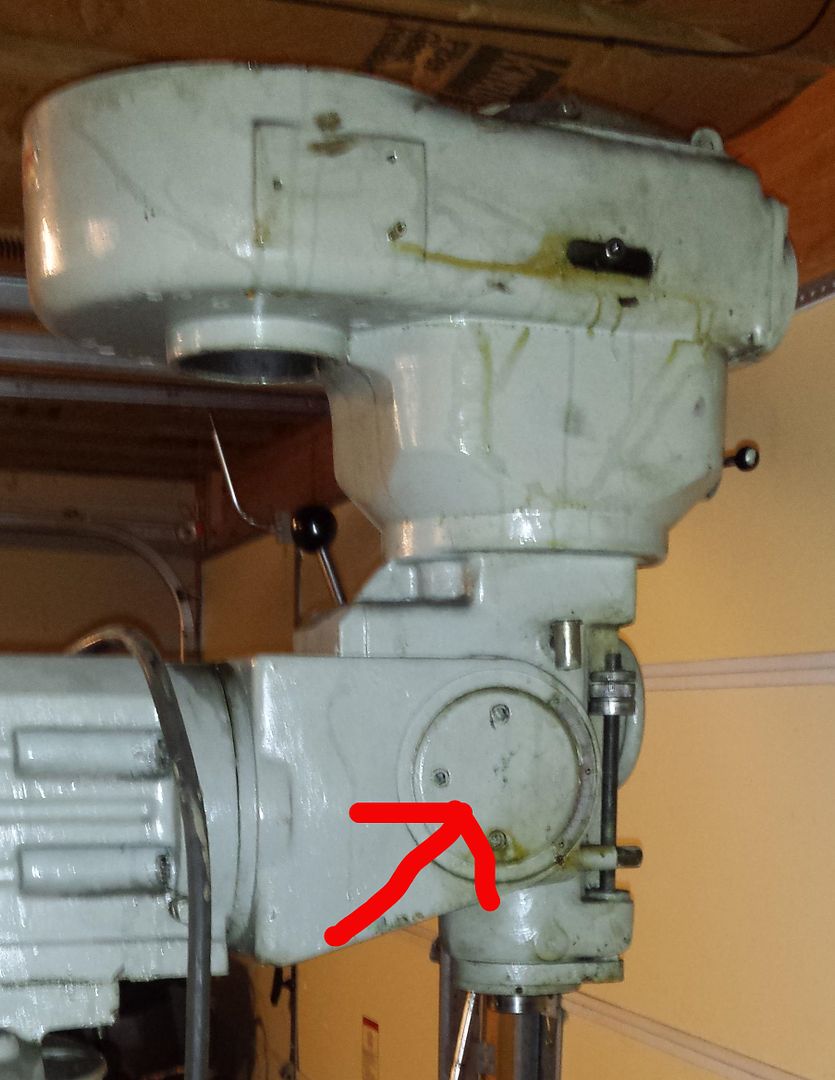

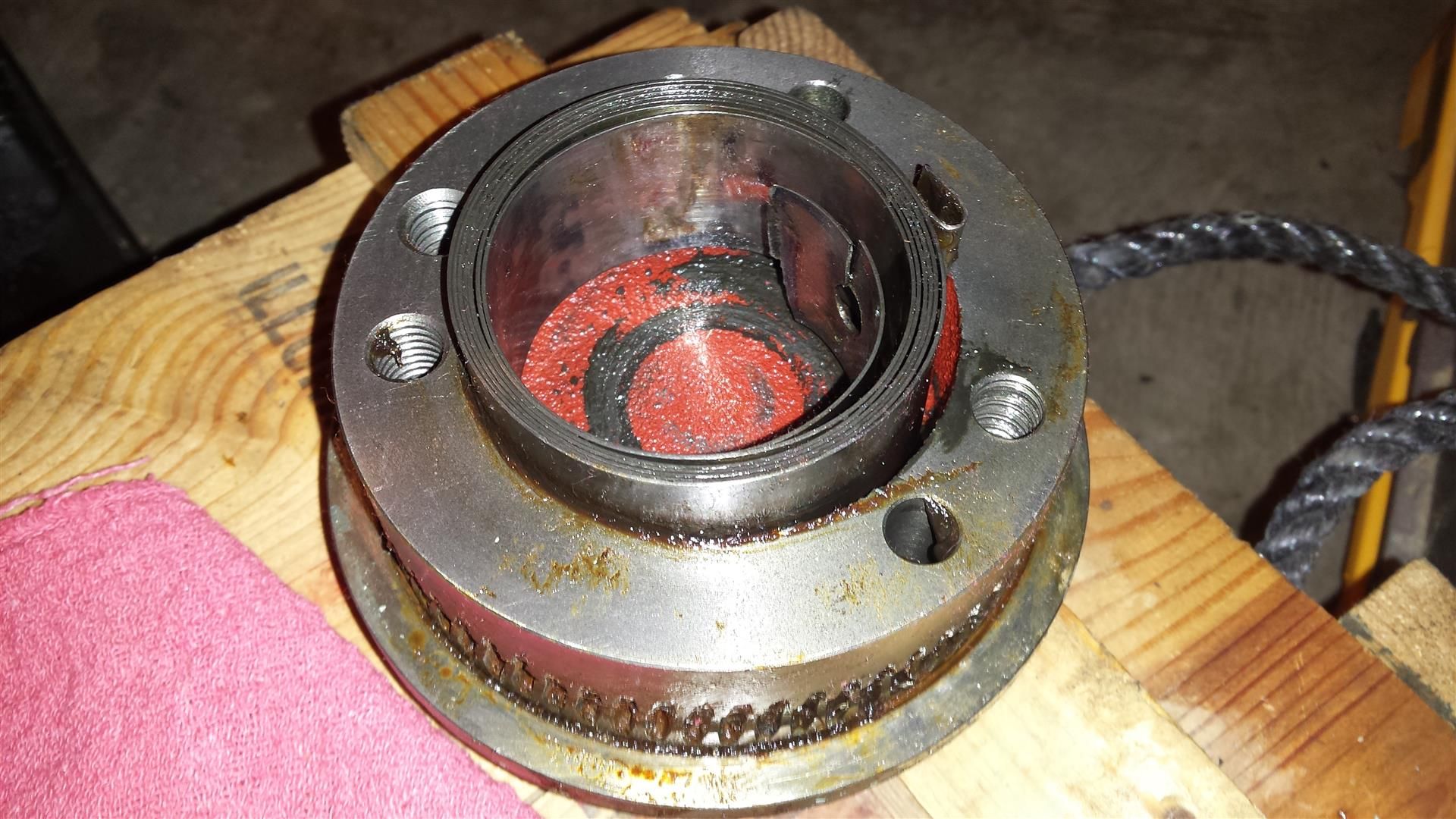

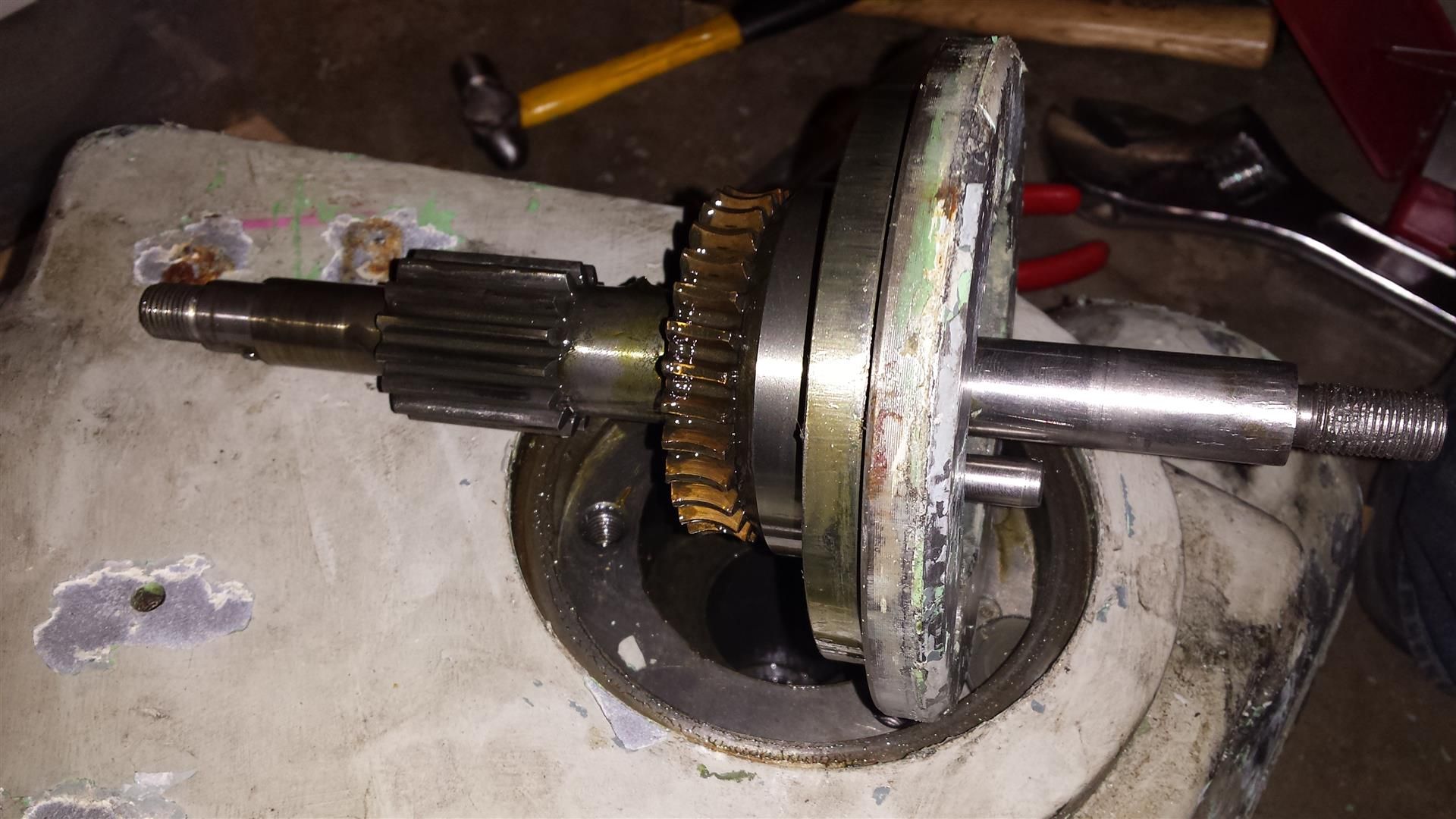

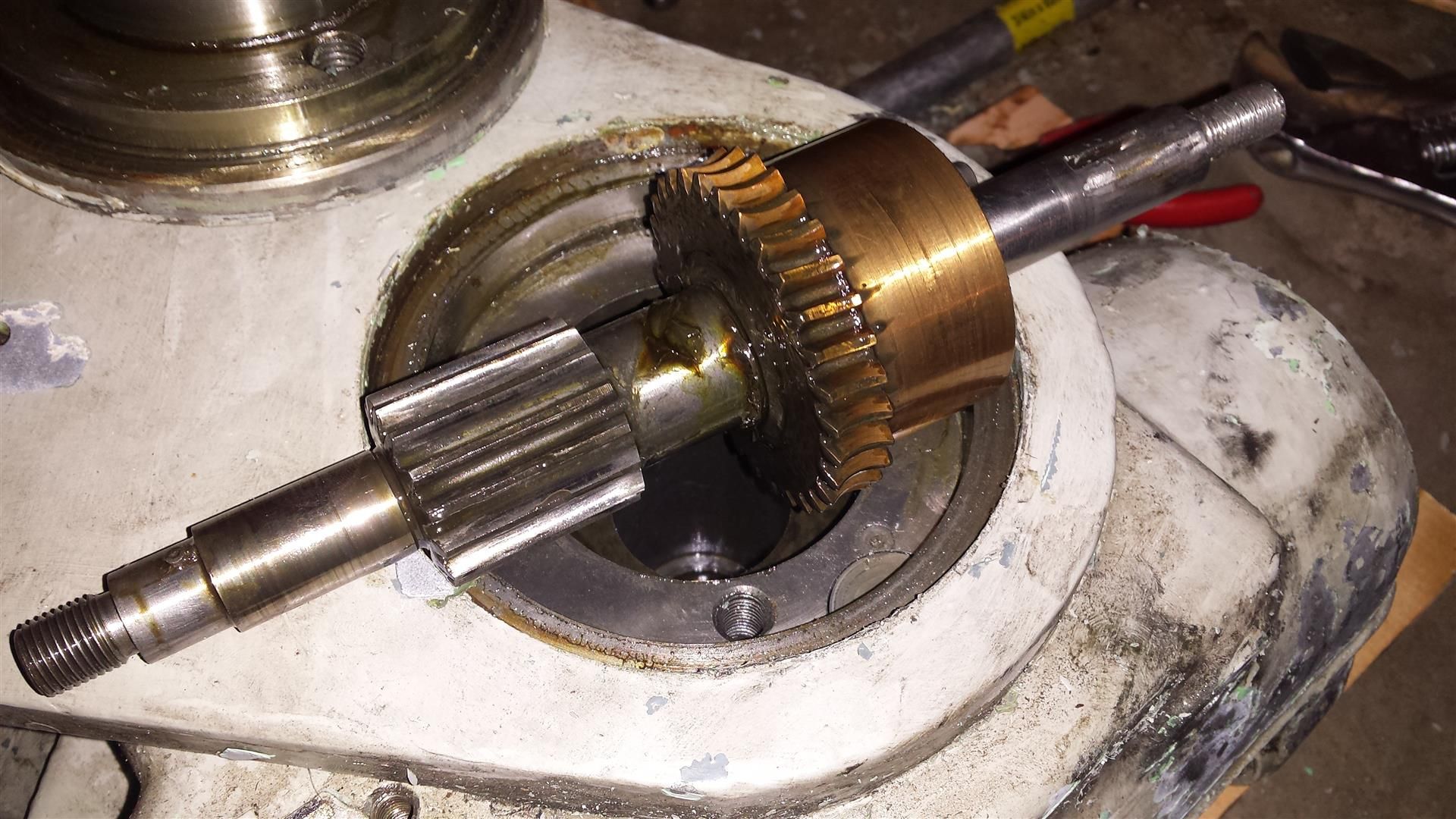

Hello everyone, this is my first personal mill and would like some help in its disassembly. I've removed the head and was able to remove the upper portion (motor housing) and middle portion (gearbox) of the head. Now I'm left with the lower section of the head that houses the gears that drive the fine down feed. I opened up the back where the gears are located and was able to remove them (along with a lifetime supply of grease that came out of it). Now all that's left is the quill lever gear and the knuckle/yoke that the head pivots up and down on.

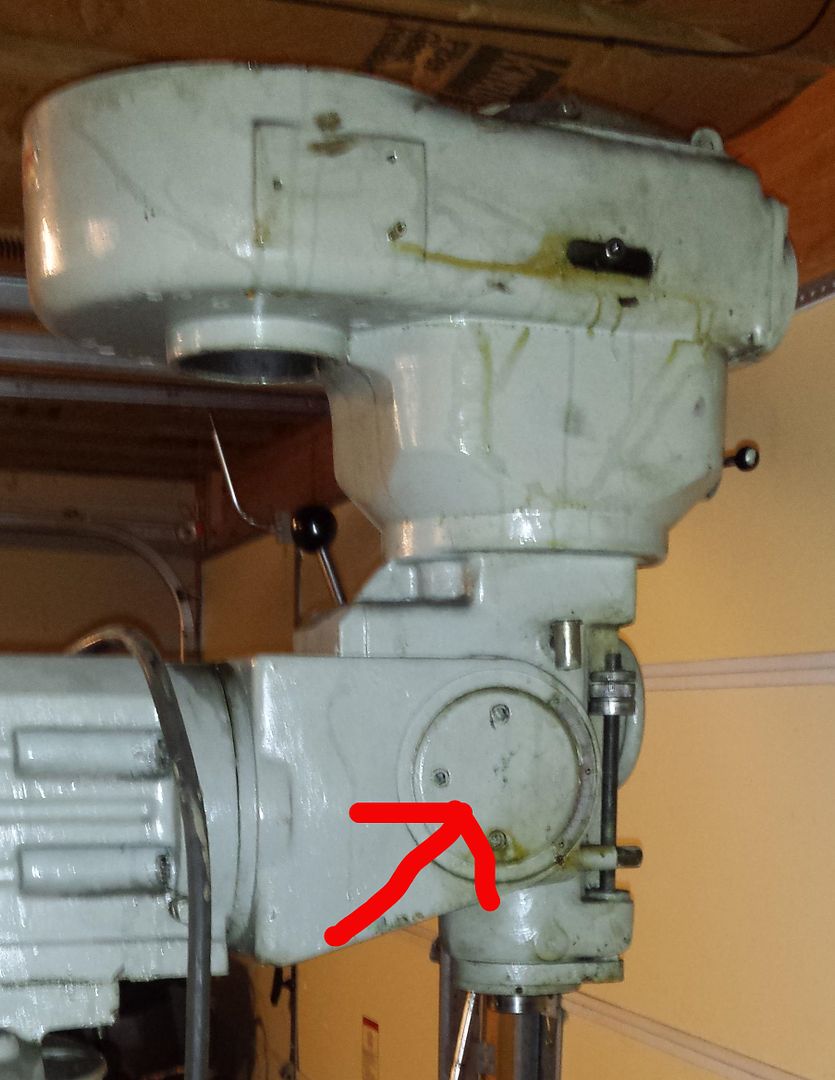

The pictured cap seems to be what's holding up the progress, but I can't figure out how to remove it. I've already removed the three bolts but can't find a seam to pry it off. I know that a few of you have broken these down before in the past so I'm hoping some of you will have the answers. I'm sure I'll have more questions as I progress through this.

Any and all suggestions would be greatly appreciated.

The pictured cap seems to be what's holding up the progress, but I can't figure out how to remove it. I've already removed the three bolts but can't find a seam to pry it off. I know that a few of you have broken these down before in the past so I'm hoping some of you will have the answers. I'm sure I'll have more questions as I progress through this.

Any and all suggestions would be greatly appreciated.