pfridl

Plastic

- Joined

- Nov 20, 2007

- Location

- Birmingham AL

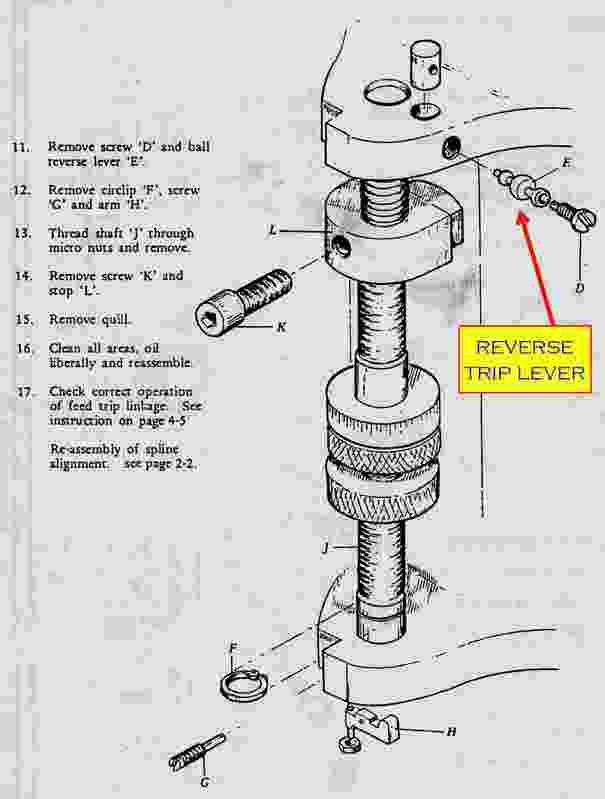

I need to remove the feed reverse and feed trip bracket assembly from my J-head. The bracket is broken and needs to be removed for repair. I have loosened the bolts but it does not seem to want to come off easily as an assembly so I'm guessing there's a bit more to it. Can anyone describe the process of removal to help me out?

Thanks, Paul.

Thanks, Paul.