Just to keep it short if you don't want to read the stuff below, Which kind of bridgeport power feed handle do you prefer? The Pin engagement type or the twist to engage type? I have only used the pin type and have no idea.

I have a Series II special. Made about 1986. By all signs it never had much use before I bought it. However, the engagement of the handle on the X axis drive motor never worked well. It slips out easily.

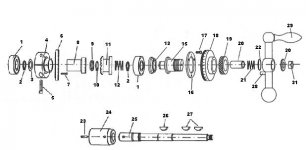

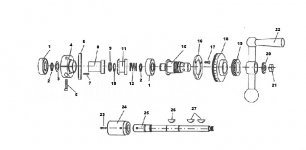

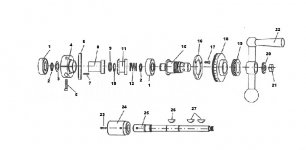

I say Frankenstein because according to the diagrams for an 8F or 6F It should have a twist to engage handle. It has the faceplate nose of a 6F-c or 8F. However it has a non twist to engage handle (late model with black counterweight like an 8F), and it looks like it has a dial holder (internal part) of a 6A-B that uses a pin engagement on the handle.

The handle has a pin for engagement, but it and the dial holder are buggered and lets it slip.

looks like I will need to replace the dial holder at least, but I could upgrade the parts to a twist to engage with no trouble.

I have a Series II special. Made about 1986. By all signs it never had much use before I bought it. However, the engagement of the handle on the X axis drive motor never worked well. It slips out easily.

I say Frankenstein because according to the diagrams for an 8F or 6F It should have a twist to engage handle. It has the faceplate nose of a 6F-c or 8F. However it has a non twist to engage handle (late model with black counterweight like an 8F), and it looks like it has a dial holder (internal part) of a 6A-B that uses a pin engagement on the handle.

The handle has a pin for engagement, but it and the dial holder are buggered and lets it slip.

looks like I will need to replace the dial holder at least, but I could upgrade the parts to a twist to engage with no trouble.