regcabdak

Cast Iron

- Joined

- Jan 9, 2008

- Location

- northern california

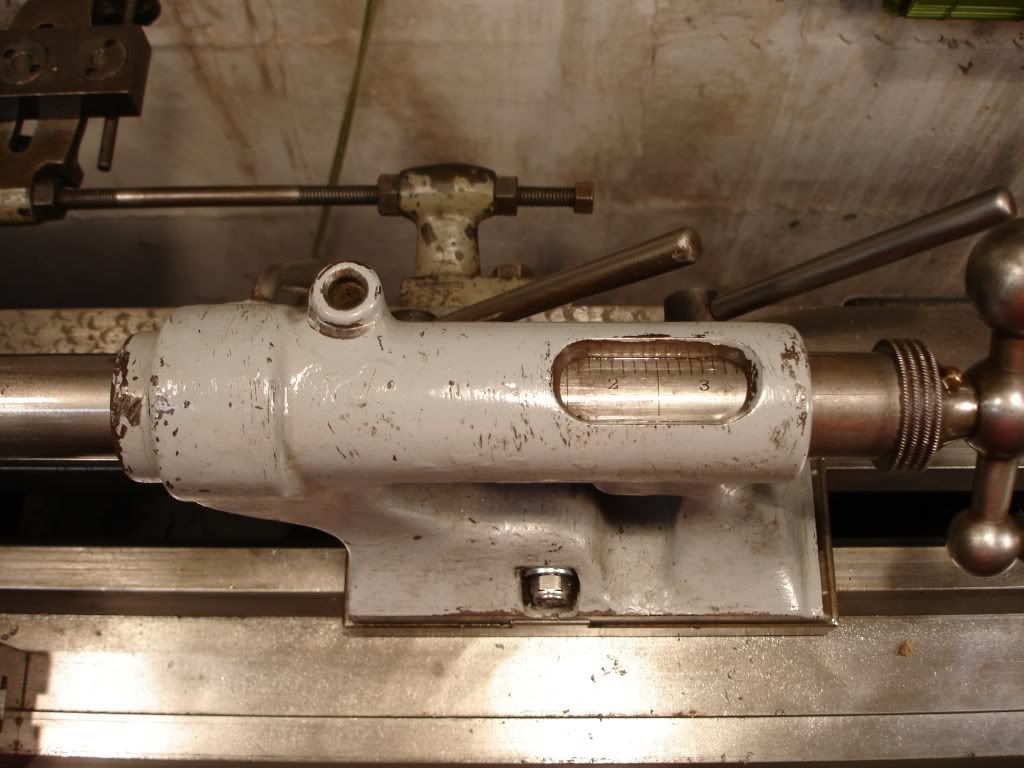

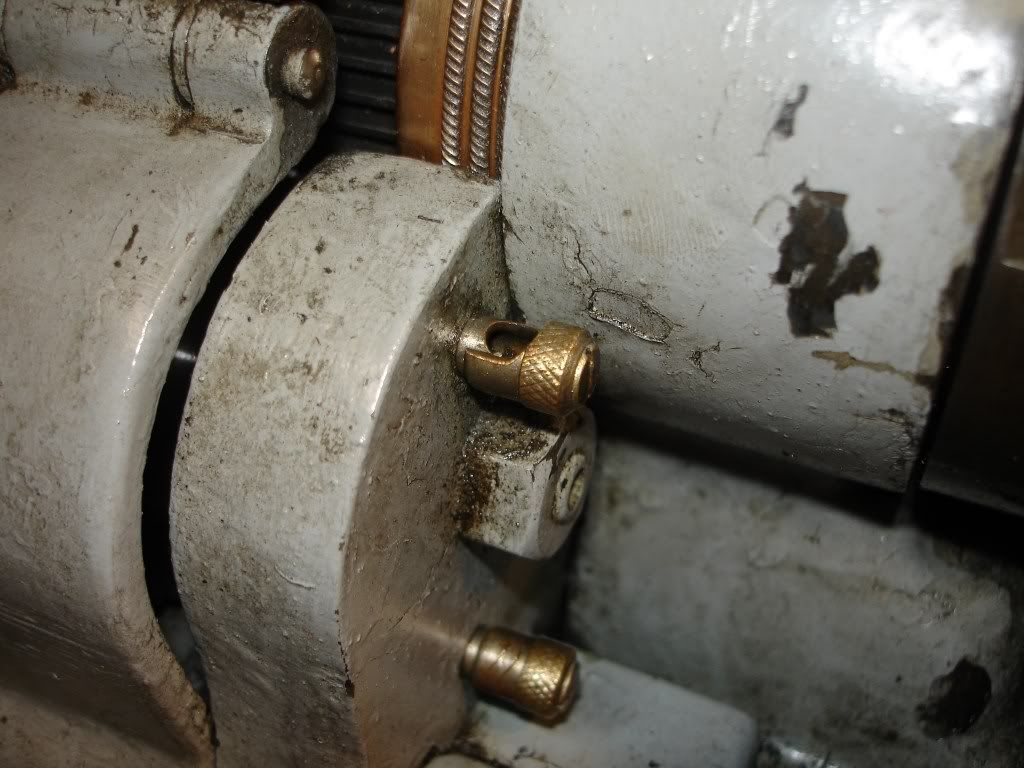

I was wondering if anyone has an original tailstock white lead "dauber" from either an early Hardinge or Cataract lathe. I was hoping someone could post a picture and maybe a few measurements so I can make a copy. I will most likely not use the dauber, but im tired of looking at the empty hole in the tailstock, and it will be a quick little project.

Thanks!

Tyler

Thanks!

Tyler