billyjack

Plastic

- Joined

- Feb 21, 2006

- Location

- Inman, South Carolina

Hey Guys and Gals.

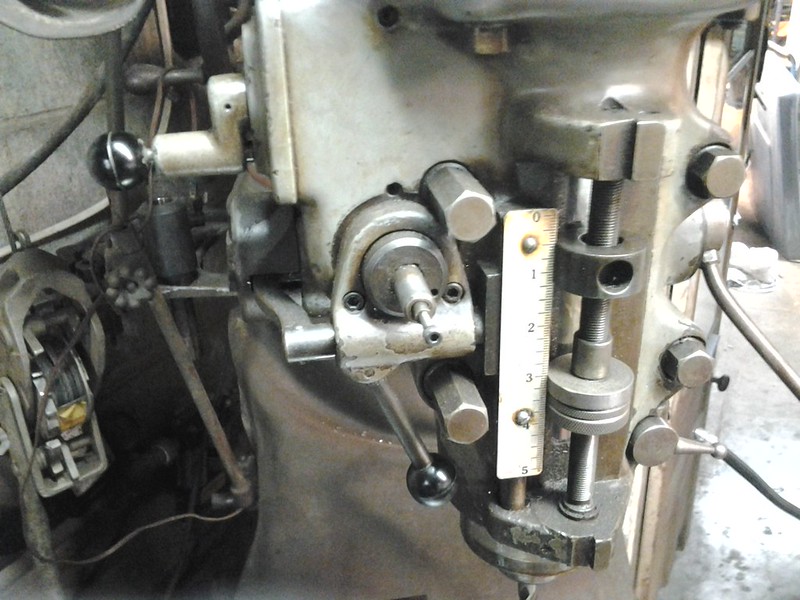

I'm new to bridgeport operation and have no idea how the quill feed is suppose to work. I have the trip lever adjusted to it trips out but is the quill suppose to reverse???? I just today replaced the feed reverse knob and can't get it to do anything. It's suppose to be a three position with up, neutral, and down as selection. Mine doesn't do anything!!! Any idea why. Also, the feed when engaged comes down to the trip point and trips out the clutch. Is it suppose to reverse??? I have a decent parts manual but the operational part is lacking but the illustrations are pretty good. Can someone help. I love this old machine.

Bill

I'm new to bridgeport operation and have no idea how the quill feed is suppose to work. I have the trip lever adjusted to it trips out but is the quill suppose to reverse???? I just today replaced the feed reverse knob and can't get it to do anything. It's suppose to be a three position with up, neutral, and down as selection. Mine doesn't do anything!!! Any idea why. Also, the feed when engaged comes down to the trip point and trips out the clutch. Is it suppose to reverse??? I have a decent parts manual but the operational part is lacking but the illustrations are pretty good. Can someone help. I love this old machine.

Bill