Hello, I just recently picked up an old Hardinge lathe that I'd like to restore/fix if possible. From the research I've done I think it's a quick change swing style lathe, date mark on the tail end of the bed reads 25. There is a stamped plate on the headstock that reads L1191. I've seen pictures and illustrations of similar lathes but I don't think this is a toolroom model with the threading gears on the headstock. It has a pretty sloppy paintjob, in some places where there probably shouldn't be paint. Spindle is smooth but very tight/difficult to turn. Came with a crossslide that I'm sure isn't original.

I'll try and have a link to the album with the pictures I took of it on this post. This is my first thread so please bear with me if I haven't done this correctly.

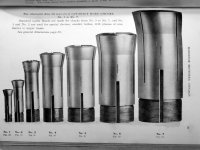

I've seen a few catalogues with similar models but i haven't seen mention of a turret setup. I'm hoping that someone with more knowledge about these old Hardinge lathes can shed some light on what parts are original, what's hacked together and maybe if it's even salvageable? Mostly I'm having trouble figuring out how to remove the spindle. With the little research I've done I guess these older headstocks are pretty complex inside? Only place I see that could receive a wrench for unscrewing the spindle is some notching on the back end, any better ideas?

Thanks for taking the time to read,

Xavier

XavierC57's Library | Photobucket

I'll try and have a link to the album with the pictures I took of it on this post. This is my first thread so please bear with me if I haven't done this correctly.

I've seen a few catalogues with similar models but i haven't seen mention of a turret setup. I'm hoping that someone with more knowledge about these old Hardinge lathes can shed some light on what parts are original, what's hacked together and maybe if it's even salvageable? Mostly I'm having trouble figuring out how to remove the spindle. With the little research I've done I guess these older headstocks are pretty complex inside? Only place I see that could receive a wrench for unscrewing the spindle is some notching on the back end, any better ideas?

Thanks for taking the time to read,

Xavier

XavierC57's Library | Photobucket