LOU_BRICANT

Plastic

- Joined

- Apr 25, 2018

Hello All,

First post on here. I've been an active reader on the forum for a while, but haven't become a member until now (since I'm in a pinch).

CAM Export Program: CAMWorks 2017

Machine: Bridgeport w/ SWI TRAK AGE 2 - .cam programs imported via 3 1/2 floppy A

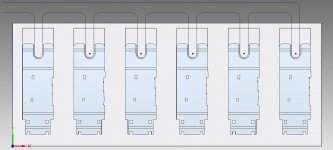

Below I have attached G code of the program for reference, as well as a snapshot of the tool I'm working with.

I have compared the dimensions of the tool and the CAD model, and it is correct within acceptable standards.

The setup in the vise and the origin were verified as correct prior to machining the first run of parts.

I double checked that the program values for the tool path matched CAD when imported into the machine.

The Bridgeport table/Trak AGE calibration was checked and verified as acceptable.

Here is the problem - when the program is executed, pocket #1 machined as expected, but pockets #2-6 progressively became worse, with the chamfer contours shifting in the X+ direction only, despite the Prototrak display the correct tool path values.

Is there a known issue with certain file formats causing a compounding shift in tool path??

Thank you all for your help in advance!

View attachment 13102.txt

First post on here. I've been an active reader on the forum for a while, but haven't become a member until now (since I'm in a pinch).

CAM Export Program: CAMWorks 2017

Machine: Bridgeport w/ SWI TRAK AGE 2 - .cam programs imported via 3 1/2 floppy A

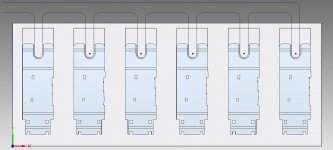

Below I have attached G code of the program for reference, as well as a snapshot of the tool I'm working with.

I have compared the dimensions of the tool and the CAD model, and it is correct within acceptable standards.

The setup in the vise and the origin were verified as correct prior to machining the first run of parts.

I double checked that the program values for the tool path matched CAD when imported into the machine.

The Bridgeport table/Trak AGE calibration was checked and verified as acceptable.

Here is the problem - when the program is executed, pocket #1 machined as expected, but pockets #2-6 progressively became worse, with the chamfer contours shifting in the X+ direction only, despite the Prototrak display the correct tool path values.

Is there a known issue with certain file formats causing a compounding shift in tool path??

Thank you all for your help in advance!

View attachment 13102.txt