I never thought I would be asking for a Cad recommendation here but until a few weeks ago I never tried to 3d model a house in solidworks.

Certain things in SW just annoy me and one is 3d sketch. I have always tried to avoid it by shifting plains around. I have also never used weldments until recently and I absolutely despise it as it requires 3d sketch and then works everything off centerline. Weldments then mate weldment assemblies have me fuming.

In the Philippines land is cheap and construction is cheaper. Problem is if you don't draw it on a napkin while downing some hi octane Filipino beer with the builder they are lost. Usually when someone wants a house built its sketched out and the builder literary shoots from the hip. No planning, no material list just a shape and a mental picture.

Studs here are non existent so all houses are built from regular 16" construction blocks since the’re only .11 cents a pop. Problem with that is no houses here have insulation, just a 6" thick wall with a year round 90+ degree temp. Most roofs are corrugated metal or grass Nippa with maybe a 3/8" thick aluminum foil sided foam sheet.

I managed to pick up a few hectares of land and I'm building some 14X20 elevated beach bungalows but I want to change it up to a more western build but keep it native looking. My plan is to build 8 Pillars 8' tall supporting a metal truss floor then use C purlins for the wall studs and roof braces. My plan for the roof is corrugated metal with Nippa on top than 2" foam on the inside covered by Sawali (Woven Bamboo mat).

As it stands I have a (Buildable) model in solidworks with a BOM and dimensioned drawings. For me, I could build from what I have but these workers here are absolutely lost. I drew the columns and the foundation flooring and told them to put Re-bar in just like any other concrete job but I want 4 pieces coming out the top on 2.5" centers to weld the main flooring frame to. Nope,,,, now they want dimensioning for all the rebar as well as the cages and then they want drawings for the column forms.

Shaking my head I go back in my office and start to model fkn Re-bar! What a PITA in Solidworks. As Im modeling this the guy ask where I want the windows. Ooopps, It was at this point I realised I don't know how to sketch/extrude through the row of studs I modeled using pattern repeat. Now they are really confused and want to just not do the job period.

I really can't get too upset with the builders as this is nothing like they have ever built before. fro most its block, cement, and bamboo. with Portland Cement only $2.40 for an 80# bag I can't really blame them. I'm looking at the fac t we get 5-10 Typhoons a year and twice that in tropical depressions. 140 Kilometer winds 10' up in the air I don't want to fly away. A 2x4x1/8x20 rectangular tubing is $9.30 a piece. 2x3x.080x20' C purlin is about $6 a pop. My plan is to make the floor joist from the 2x4 metal tube and the wall and roof studs from the C purlins then cover it all in Woven bamboo sheeting.

For the most part I can get these done in SW but its takes a lot of time and I plan on each place being different. Sorry for the long (Kinda OT) post but just wanted to give a general idea of what i'm trying to get out of a software. I figured here would be the best place to ask if theres any architects in the group or if someone can tell me how to sketch/extrude cut through a pattern from a different plain in SW.

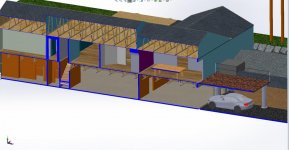

Here's a couple of pics of what i'm trying to accomplish.

Certain things in SW just annoy me and one is 3d sketch. I have always tried to avoid it by shifting plains around. I have also never used weldments until recently and I absolutely despise it as it requires 3d sketch and then works everything off centerline. Weldments then mate weldment assemblies have me fuming.

In the Philippines land is cheap and construction is cheaper. Problem is if you don't draw it on a napkin while downing some hi octane Filipino beer with the builder they are lost. Usually when someone wants a house built its sketched out and the builder literary shoots from the hip. No planning, no material list just a shape and a mental picture.

Studs here are non existent so all houses are built from regular 16" construction blocks since the’re only .11 cents a pop. Problem with that is no houses here have insulation, just a 6" thick wall with a year round 90+ degree temp. Most roofs are corrugated metal or grass Nippa with maybe a 3/8" thick aluminum foil sided foam sheet.

I managed to pick up a few hectares of land and I'm building some 14X20 elevated beach bungalows but I want to change it up to a more western build but keep it native looking. My plan is to build 8 Pillars 8' tall supporting a metal truss floor then use C purlins for the wall studs and roof braces. My plan for the roof is corrugated metal with Nippa on top than 2" foam on the inside covered by Sawali (Woven Bamboo mat).

As it stands I have a (Buildable) model in solidworks with a BOM and dimensioned drawings. For me, I could build from what I have but these workers here are absolutely lost. I drew the columns and the foundation flooring and told them to put Re-bar in just like any other concrete job but I want 4 pieces coming out the top on 2.5" centers to weld the main flooring frame to. Nope,,,, now they want dimensioning for all the rebar as well as the cages and then they want drawings for the column forms.

Shaking my head I go back in my office and start to model fkn Re-bar! What a PITA in Solidworks. As Im modeling this the guy ask where I want the windows. Ooopps, It was at this point I realised I don't know how to sketch/extrude through the row of studs I modeled using pattern repeat. Now they are really confused and want to just not do the job period.

I really can't get too upset with the builders as this is nothing like they have ever built before. fro most its block, cement, and bamboo. with Portland Cement only $2.40 for an 80# bag I can't really blame them. I'm looking at the fac t we get 5-10 Typhoons a year and twice that in tropical depressions. 140 Kilometer winds 10' up in the air I don't want to fly away. A 2x4x1/8x20 rectangular tubing is $9.30 a piece. 2x3x.080x20' C purlin is about $6 a pop. My plan is to make the floor joist from the 2x4 metal tube and the wall and roof studs from the C purlins then cover it all in Woven bamboo sheeting.

For the most part I can get these done in SW but its takes a lot of time and I plan on each place being different. Sorry for the long (Kinda OT) post but just wanted to give a general idea of what i'm trying to get out of a software. I figured here would be the best place to ask if theres any architects in the group or if someone can tell me how to sketch/extrude cut through a pattern from a different plain in SW.

Here's a couple of pics of what i'm trying to accomplish.

I have built several buildings in my lifetime and I am just weeks away from completing a new shop. I applaud you for trying to design and build this project.

I have built several buildings in my lifetime and I am just weeks away from completing a new shop. I applaud you for trying to design and build this project.