maikol2346

Plastic

- Joined

- Jan 23, 2020

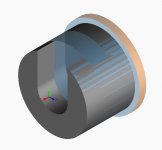

Image 1

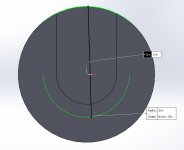

Image 2

Image 3

Image 4

Hello everyone,

I am a beginner at SolidWorks CAM and I am encountering some trouble machining the slot inside of that button part. As you can see in image 1, I already have most of the part figured out except for that blue area. I have tried defining the feature as a pocket and when I attempt to do a contour operation it only trims off the top and goes around. When I try defining the feature as a slot, it doesn't create a path for a contour operation. I am using a 2.5 axis mill to make this part. Dimensions can be seen in images 2 and 3. It's a 0.25" x 0.63" x 0.81" slot. I should also add that I am using a keycutter with the dimensions specified in image 4.