Sparky961

Cast Iron

- Joined

- Jul 10, 2008

- Location

- Vancouver Island, BC, Canada

This is, I hope, a question for which there's a really simple answer. Though I've poked around a bit on the interweb, I haven't found anything that answers it or haven't been looking for the right thing.

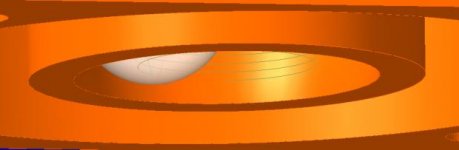

In MasterCAM (X4, not that it matters much), I'm trying to machine an internal "funnel" shape. I'd love to do this on a CNC lathe but with my current machine choices interpolating on a mill is the better option. What I can't seem to figure out is how to get the toolpath to completely machine the surface.

I hope you can see from the attached screenshots that the toolpath only extends down such that the tip of the ballnose endmill is at the bottom of the part. I want it to continue down far enough that the entire face is cleaned up. I've experienced this before and have usually found a way to fudge it and make things work, but I've run out of things to try.

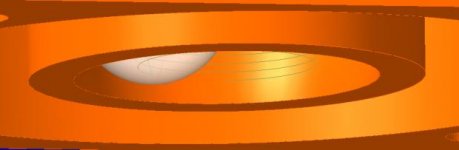

In MasterCAM (X4, not that it matters much), I'm trying to machine an internal "funnel" shape. I'd love to do this on a CNC lathe but with my current machine choices interpolating on a mill is the better option. What I can't seem to figure out is how to get the toolpath to completely machine the surface.

I hope you can see from the attached screenshots that the toolpath only extends down such that the tip of the ballnose endmill is at the bottom of the part. I want it to continue down far enough that the entire face is cleaned up. I've experienced this before and have usually found a way to fudge it and make things work, but I've run out of things to try.