I think I found the solution to my problem. Someone pointed out to me that you can change the compensation method in the tool set up, which makes sense.

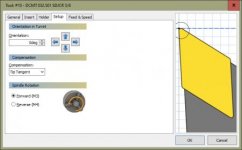

The problem was the tool center method used to calculate the toolpath. It turns out Fusion/HSMWorks has a pull down in the tool set up. The tool was using the default compensation method of TIP TANGENT in the set up

View attachment 333643

Which gave me these tool paths, that ran the tool right along the part surface, which caused my lathe to cut the parts undersized because of the way the lathe handles the compensation.

View attachment 333642

By going into the tool setup tab and changing the compensation to TIP CENTER, the problem seems to be solved, at least by looking at the generated toolpaths.

View attachment 333645

Now the tool path is off of the part by the tip radius. This should give me a good result.

View attachment 333644

Mike

Assuming you touch your turning tool off in X and Z as per normal, using "in computer" (as opposed to "in control") works fine if all your features are orthogonal (no tapers, geometry-critical chamfers, curved profiles etc) because you can still comp the tool in X and Z on the machine. That means if you're taking a cut in Z at a fixed X value, it'll be completely fine with Tip Tangent and In Computer settings. For those orthogonal features, it will also post geometrically correct g-code (ie facing off will be done at Z0.000) but for any movement using both X and Z axes simultaneously (non-orthogonal features) if using "in computer" the code will shift the tool's imaginary tip (what the control records when you touch it off as though you have a completely square insert with no radius) in whichever direction Fusion determines that it needs to, so if you have a taper that goes from say X0.500 Z0.000 to X1.000 Z-0.250 (a 45 degree chamfer) it will offset the coordinates in the g-code in either X or Z (or both) to ensure that the radiused tip of the tool stays in contact with the taper.

It will have a potential error on non-orthogonal (tapered/compound) surfaces that is whatever the error in the insert radius is, because as above, it'll adjust the X and Z values for tapered surface in the G-code. By this I mean that if your G-code is spat out thinking you've got say an 0.008" radius on the insert but you're actually using an 0.016" TNR then it'll be slightly off on those surfaces where it is not just cutting in one axis only (ie only a Z movement, or only an X movement. This means that if you're using In Computer compensation, you must repost the code if you use a different insert radius. If all features are orthogonal, there's no radii or tapers, it doesn't matter what the tool nose radius is.

If you use "in control" then it generates G41/42 compensation codes that basically tell the controller exactly what the part geometry is, rather than where to put the insert based on where it thinks the imaginary tip is, if there were a zero radius, based on where you touched off in X and Z. In those cases the G-code should always exactly match the actual part geometry because the G41/42 codes tell the controller to consider the tool nose radius which you enter at the control (if G41/42 are not active, ie if G40 is active, then tool nose radius is ignored by the control, it just assumes the TNR is zero).

In my opinion, "tip tangent" is always the correct compensation to use - using "tip" or "tip center" (or especially "insert center", wtf fusion) does not make sense in any case I can think of. I'd recommend steering clear of "in control" too for most applications because as someone else said, it can create all kinds of errors/alarms (like if you tell the tool to cut in Z then up/out in X without specifying a linking radius) because it is trying to match the tool radius in the control, to the specified geometry in the g-code, and obviously you can't actually get a radiused insert into a sharp corner. G41/42 are highly necessary with milling tools but mostly a waste of time for turning because you can already comp the tool in x and z to change size of a feature.

It is frankly confusing as hell though and Autodesk don't do a very good job of explaining it IMO. There is a reasonably good explanation of all the options here -

Solved: Tool tip used in turning, right and wrong choice. - Autodesk Community