How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

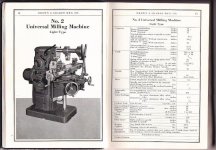

Brown@sharpe #2 universal lite milling machine

- Thread starter usace

- Start date

- Replies 8

- Views 3,537

johnoder

Diamond

- Joined

- Jul 16, 2004

- Location

- Houston, TX USA

ramsay1

Titanium

- Joined

- Aug 19, 2003

- Location

- port allen, louisiana usa

Draw Bolt Brown and Sharpe

Found this in an old B&S book I have had for years.. Hope it helps!

As late as 1951, I have found this type of bolt.. You will probably just have to make one to suit your needs.. On your machine you probably have 40 std spindle which should use 5/8-11 thread on the arbor end...You will have to measure from the inside of the threaded hole of an arbor placed all the way in your spindle and go from there.. Ramsay 1

I have a 1944 #2 brown@sharpe universal lite horizontal milling machine and need someone to post a picture and length of a draw bar that fits this machine. I'm going to make one and want it to look original.Thanks

Found this in an old B&S book I have had for years.. Hope it helps!

As late as 1951, I have found this type of bolt.. You will probably just have to make one to suit your needs.. On your machine you probably have 40 std spindle which should use 5/8-11 thread on the arbor end...You will have to measure from the inside of the threaded hole of an arbor placed all the way in your spindle and go from there.. Ramsay 1

Attachments

I know that this is an old thread, but I recently acquired a B&S No.2 Universal... it was given to me and I’m trying to resurrect it after years of sitting. The machine was oiled regularly by the old timer that gave it to me and there was a piece of all-thread with a nut and a knurled knob on the end of it sitting on the table of the machine. I made sure that I took it when I moved the machine because it looked like the old timer was in the middle of something and then just stopped...and never came back to it for years. I now expect (after examining the machine closely) that he was making a new draw-bolt for the horizontal axis (fed through the doorway on the back of the main tower).

Three questions: (1) the machine is set up currently with one of its vertical cutting heads (I t also came with the horizontal head and spindle supports and another vertical cutting head of a different speed), does the vertical machine head require the draw bolt from the rear doorway (the horizontal draw bolt) to function in the vertical configuration?

(2) how long is the draw bolt supposed to be? The all thread left by the gentlemen doesn’t seem long enough to engage anything in the machine currently.

(3) What is the name of the book you referenced from Brown & Sharpe that might have more information on my No.2? I’ve ordered a copy of the Brown & Sharpe Practical Treatise for Milling and Milling machines referenced in a digital copy of the manual I found buried in another forum post.

I’m 33 and have no experience with Milling Machines, but I’ve always wanted to learn. This machine was given to me for free (except the cost of my moving it and the elbow grease of getting it cleaned up). This machine has a war production badge and I think the serial number is 9407 so I’m guessing it was produced sometime in the early 1940s. I’m hoping the electrical connections won’t be too difficult and I can get the thing running again. Any assistance in information is greatly appreciated.

Three questions: (1) the machine is set up currently with one of its vertical cutting heads (I t also came with the horizontal head and spindle supports and another vertical cutting head of a different speed), does the vertical machine head require the draw bolt from the rear doorway (the horizontal draw bolt) to function in the vertical configuration?

(2) how long is the draw bolt supposed to be? The all thread left by the gentlemen doesn’t seem long enough to engage anything in the machine currently.

(3) What is the name of the book you referenced from Brown & Sharpe that might have more information on my No.2? I’ve ordered a copy of the Brown & Sharpe Practical Treatise for Milling and Milling machines referenced in a digital copy of the manual I found buried in another forum post.

I’m 33 and have no experience with Milling Machines, but I’ve always wanted to learn. This machine was given to me for free (except the cost of my moving it and the elbow grease of getting it cleaned up). This machine has a war production badge and I think the serial number is 9407 so I’m guessing it was produced sometime in the early 1940s. I’m hoping the electrical connections won’t be too difficult and I can get the thing running again. Any assistance in information is greatly appreciated.

texasgeartrain

Titanium

- Joined

- Feb 23, 2016

- Location

- Houston, TX

Brown and Sharpe made stuff for a long long time, so depending what year, a machine could be way different. There are different kinds of #2 machines also. Some pics will help.

Click the "date" tab, and the pubs will organize better:

Brown & Sharpe Mfg. Co. - Publication Reprints | VintageMachinery.org

Click the "date" tab, and the pubs will organize better:

Brown & Sharpe Mfg. Co. - Publication Reprints | VintageMachinery.org

z.....to answer your questions.

(1) No you do not use the draw bolt to secure the vertical head or attachments like a slotter with the draw bolt. they bolt to the face of the machine. The vertical head is driven by the two "lugs" on the face of the horizontal spindle which drive the #40 Taper arbors.

(2) The all thread that is too short may be for the vertical head. It should need a draw bar too.

(3) The pages ramsey1 posted are from a Brown & Sharpe machine tool catalog. Does the machine manual you downloaded say "for machines beginning with serial #6153" on the front page? I have a copy of that manual.

I have parts from a #2 light horizontal B & S mill that was dropped at a scrap yard. Drawbar, hand wheels, levers, table stops, complete electrical panel, ect. Oh, yeah, I also saved the two overarm supports for my Brown & Sharpe Omniversal mill. If you are missing some parts, let me know.

If you are missing some parts, let me know.

(1) No you do not use the draw bolt to secure the vertical head or attachments like a slotter with the draw bolt. they bolt to the face of the machine. The vertical head is driven by the two "lugs" on the face of the horizontal spindle which drive the #40 Taper arbors.

(2) The all thread that is too short may be for the vertical head. It should need a draw bar too.

(3) The pages ramsey1 posted are from a Brown & Sharpe machine tool catalog. Does the machine manual you downloaded say "for machines beginning with serial #6153" on the front page? I have a copy of that manual.

I have parts from a #2 light horizontal B & S mill that was dropped at a scrap yard. Drawbar, hand wheels, levers, table stops, complete electrical panel, ect. Oh, yeah, I also saved the two overarm supports for my Brown & Sharpe Omniversal mill.

If you are missing some parts, let me know.

If you are missing some parts, let me know.z.....to answer your questions.

(1) No you do not use the draw bolt to secure the vertical head or attachments like a slotter with the draw bolt. they bolt to the face of the machine. The vertical head is driven by the two "lugs" on the face of the horizontal spindle which drive the #40 Taper arbors.

(2) The all thread that is too short may be for the vertical head. It should need a draw bar too.

(3) The pages ramsey1 posted are from a Brown & Sharpe machine tool catalog. Does the machine manual you downloaded say "for machines beginning with serial #6153" on the front page? I have a copy of that manual.

I have parts from a #2 light horizontal B & S mill that was dropped at a scrap yard. Drawbar, hand wheels, levers, table stops, complete electrical panel, ect. Oh, yeah, I also saved the two overarm supports for my Brown & Sharpe Omniversal mill.If you are missing some parts, let me know.

I would definitely be interested in a drawbar. While I'm sure I can rework one with the all thread method, I wouldn't mind having a functioning one to pattern replacements off of. I don't think the manual I downloaded had that serial number identification on it. I'll check.

Thank you all for the help and input. Last night I finally got my 3 phase converter wired up. An older electrician friend recommended tarping the machine with a shop light under the tarp for a week to make sure all the windings in the motors were dry before starting. Imagine that, I followed good advice and the machine fired right up and ran like a champ. After a few hours with some WD40 and lots of elbow grease, the machine is auto feeding in all three direction and the vertical head is spinning.

Now I'm trying to find tooling. After consulting the Practical Treatise it seems like the Vertical Head is a NMTB40 taper... what I can't seem to figure out (because this is all greek to me) is whether I need to order NMTB40 collets or Brown & Sharpe No.9 taper collets. I know the horizontal draw bar is 5/8-11 thread, but the vertical head draw bolt seems smaller and a check of the older forum threads here lead me to a picture of the No.40 draw bolt showing a 1/2-13 thread for the No. 9 BS taper collets and tools.

The machine had a cutting head in the vertical head when I got it. Last night I couldn't get it to cut at all. Every time the tool made contact with the mild steel it would stop the tool (while the spindle was still turning). I tried tightening the drawbar but it just wouldn't engage the cutting tool enough to securely hold it and keep it turning. I suspect the collet was too large for the cutting tool shaft diameter...so I'd like to figure out which set of collets to order. I would also request any recommendations for good cutters. I suspect I will predominantly be working with mild steel and aluminum. I've been trying to do a lot of reading... but 2 flutes, 4 flutes, end mills, ball nose, oh my... it gets confusing quick.

Similar threads

- Replies

- 3

- Views

- 531

- Replies

- 6

- Views

- 195