GEARS!!!???? Trying to assign values (reverse engineer) what's in my K&T 2HL

Got my 2HL universal with the vertical attachment. Luckily it came with the drive gear, however, that gear (a non-factory replacement) has no provision for drive dogs. Hence the gorilla torque used on the drawbar. I'm looking to find a good way to incorporate them into this one but decided I would learn about gears while I'm dealing with it.

What a Cluster@#$_. I have a 24T drive gear and a 23T driven splined shaft. I have no pitch gauges and trying to figure out all of the specs is overwhelming. Are there any "gearheads" that know how to speak this foreign tongue?

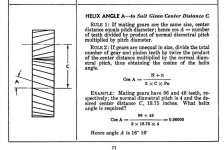

The root diameter of the 24T drive gear is 2.715", the O.D. is 3.208" the face is .986" and the angle of the gear teeth are between 28-29°. Can this be translated into a known value?

As these gears have a great propensity to go missing. I would like this post to provide information for those unfortunate enough to need a gear made from scratch by a gear company. There is a fair amount of chatter about 24T, 30T and even 32T but the formula for someone without the ability to make their own gears doesn't seem to exist.

I'll ask in advance if we could please keep the information on point for the specifics about these gears for the K&T 2HL so that it can be a solid reference for others. Other threads have wandered about the larger models and they didn't have much info to help either. Too many people wanted to add unrelated info and they went off the rails.

Here are a bunch of photos and I can get other measurements if I'm told what to look for.

Thanks

Mark

Sent from my ONEPLUS A6013 using Tapatalk

Got my 2HL universal with the vertical attachment. Luckily it came with the drive gear, however, that gear (a non-factory replacement) has no provision for drive dogs. Hence the gorilla torque used on the drawbar. I'm looking to find a good way to incorporate them into this one but decided I would learn about gears while I'm dealing with it.

What a Cluster@#$_. I have a 24T drive gear and a 23T driven splined shaft. I have no pitch gauges and trying to figure out all of the specs is overwhelming. Are there any "gearheads" that know how to speak this foreign tongue?

The root diameter of the 24T drive gear is 2.715", the O.D. is 3.208" the face is .986" and the angle of the gear teeth are between 28-29°. Can this be translated into a known value?

As these gears have a great propensity to go missing. I would like this post to provide information for those unfortunate enough to need a gear made from scratch by a gear company. There is a fair amount of chatter about 24T, 30T and even 32T but the formula for someone without the ability to make their own gears doesn't seem to exist.

I'll ask in advance if we could please keep the information on point for the specifics about these gears for the K&T 2HL so that it can be a solid reference for others. Other threads have wandered about the larger models and they didn't have much info to help either. Too many people wanted to add unrelated info and they went off the rails.

Here are a bunch of photos and I can get other measurements if I'm told what to look for.

Thanks

Mark

Sent from my ONEPLUS A6013 using Tapatalk

Last edited: