juggaloslaya

Plastic

- Joined

- Apr 7, 2015

Hey guys,

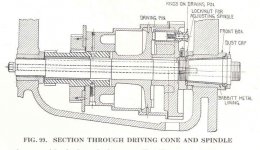

I got a very old Cincinnati horizontal mill for cheap cheap thinking pre 1920? I'm taking it apart and giving it a much needed clean.

I seem to be having some trouble getting the spindle that was holding the slitting saws off... It seems to me that its a taper that's stuck, I've given it a good whack and plenty of liquid wrench but it won't go. Does anyone have any experience with this?

Also, I am looking to run a setup with a 3/4" collet to hold hole saws, if any one can point me in the right direction for the appropriate hardware for this let me know.

see attachments for photos.

Thanks!

I got a very old Cincinnati horizontal mill for cheap cheap thinking pre 1920? I'm taking it apart and giving it a much needed clean.

I seem to be having some trouble getting the spindle that was holding the slitting saws off... It seems to me that its a taper that's stuck, I've given it a good whack and plenty of liquid wrench but it won't go. Does anyone have any experience with this?

Also, I am looking to run a setup with a 3/4" collet to hold hole saws, if any one can point me in the right direction for the appropriate hardware for this let me know.

see attachments for photos.

Thanks!