I'm starting this thread as a result of a conversation that began between me, and a couple other members about the possibility of scratch-building a few Low Lead attachments that would fit our various K&T mills,and possibly other makes as well, due to the near impossibility these days of finding suitable units in the wild. After all,if a worldwide forum full of machinists can't build a relatively simple gearbox,then I think we may be in trouble.I personally at least, am not really interested trying to do this as a "for profit" venture,as much as I am in trying to fill a need for a very hard to get,but in some cases very vital piece of tooling.

My(and hopefully our)goal would be as follows:

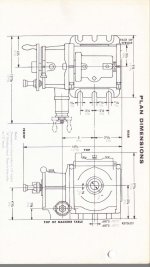

1.To gather together, and share as much information as possible about the specifications of various Low Lead, and for that matter Standard Lead attachments that fit Kearney & Trecker ,and Cincinnati as well as other makes of milling machines.

2. To use the information gathered to produce a set of working drawings for a Low Lead attachment (or attachments) that can be adaptable to fit at least a wide range of models of K&T mills, and hopefully,possibly other makes such as Cincinnati,as well others.

3. To make available those drawings to members of this community who wish to build an attachment such as this.

4. To actually build (hopefully as a cooperative effort with other members) a small number of these attachments, and use the economy gained in making more than one at a time, to make it a relatively affordable project.

I realize that this is no small task, and it will take a lot of help from friends that I haven't even met yet. It will also take time which seems to be in shorter supply every day at least for me. It won't be free, but hopefully we can use our cooperative knowledge, and resources to make it as inexpensive as possible. I will try to keep up with this thread and reply promptly as needed, but I am the Owner/operator of a one-man machine shop,with more projects, and broken down junk than I can keep running, so bear with me if it takes a few days to hear from me. I'm looking forward to seeing where this goes.

My(and hopefully our)goal would be as follows:

1.To gather together, and share as much information as possible about the specifications of various Low Lead, and for that matter Standard Lead attachments that fit Kearney & Trecker ,and Cincinnati as well as other makes of milling machines.

2. To use the information gathered to produce a set of working drawings for a Low Lead attachment (or attachments) that can be adaptable to fit at least a wide range of models of K&T mills, and hopefully,possibly other makes such as Cincinnati,as well others.

3. To make available those drawings to members of this community who wish to build an attachment such as this.

4. To actually build (hopefully as a cooperative effort with other members) a small number of these attachments, and use the economy gained in making more than one at a time, to make it a relatively affordable project.

I realize that this is no small task, and it will take a lot of help from friends that I haven't even met yet. It will also take time which seems to be in shorter supply every day at least for me. It won't be free, but hopefully we can use our cooperative knowledge, and resources to make it as inexpensive as possible. I will try to keep up with this thread and reply promptly as needed, but I am the Owner/operator of a one-man machine shop,with more projects, and broken down junk than I can keep running, so bear with me if it takes a few days to hear from me. I'm looking forward to seeing where this goes.

Ramsay 1

Ramsay 1