jubileejerry

Plastic

- Joined

- Aug 18, 2015

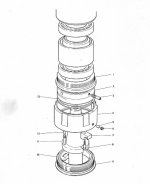

I've had this Toolmaster 1D for a few years and have never taken out the tool holder, which is a collet set-up. I have to use straight-shank tools. I have several sizes of the collets. I would like to take this off and get more choices for tooling with a different holder. I have tried to unscrew the large nut with the four slots and it will come loose, but gets hard to turn right away and I have put quite a bit of force on it but it doesn't come further. I have tried striking the top of the pull bolt like I do with my other smaller mill but it doesn't do anything. Could someone tell me what I'm doing wrong or missing here? I've studied my manual many times and just don't see much information about this.