Littledanny

Plastic

- Joined

- May 18, 2018

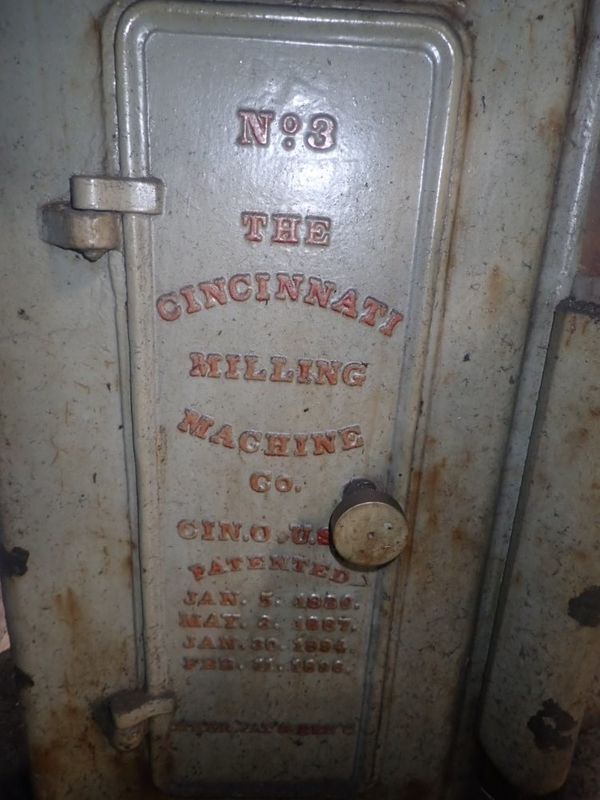

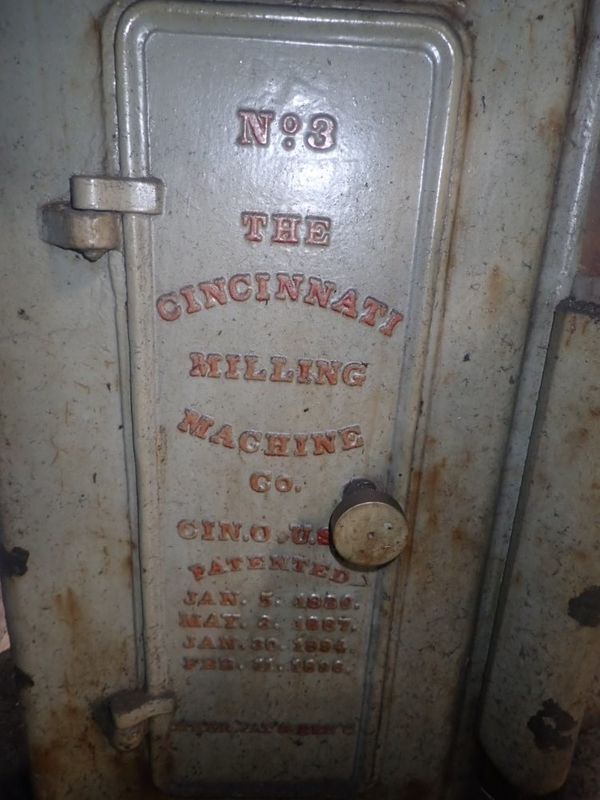

I purchased a cincinatti no3 universal horizontal mill. I have been unable to locate any documentation, other pics of similar machines, even another universal machine etc

Trying to locate manuals, figure out what year it is, location that I can find a serial number as I havent been able to find one. Pretty much whatever i can find. She seems all there the main belt was broke from what looks like deterioration as it was leather.

I have yet to get it operational but I'm looking forward to play with it. Im a hobby machinist,

I make parts for the machinery at work so this will be my first horizontal mill so I'd like to do my research on it and figure out how it functions before breaking it hence my need of a manual. Thanks in advance.

Trying to locate manuals, figure out what year it is, location that I can find a serial number as I havent been able to find one. Pretty much whatever i can find. She seems all there the main belt was broke from what looks like deterioration as it was leather.

I have yet to get it operational but I'm looking forward to play with it. Im a hobby machinist,

I make parts for the machinery at work so this will be my first horizontal mill so I'd like to do my research on it and figure out how it functions before breaking it hence my need of a manual. Thanks in advance.