How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1-5 internal acme

- Thread starter primeholy

- Start date

- Replies 10

- Views 1,634

Vargus has an online software that tells you what tool to use, it's pretty slick.

You can also download an offline version.

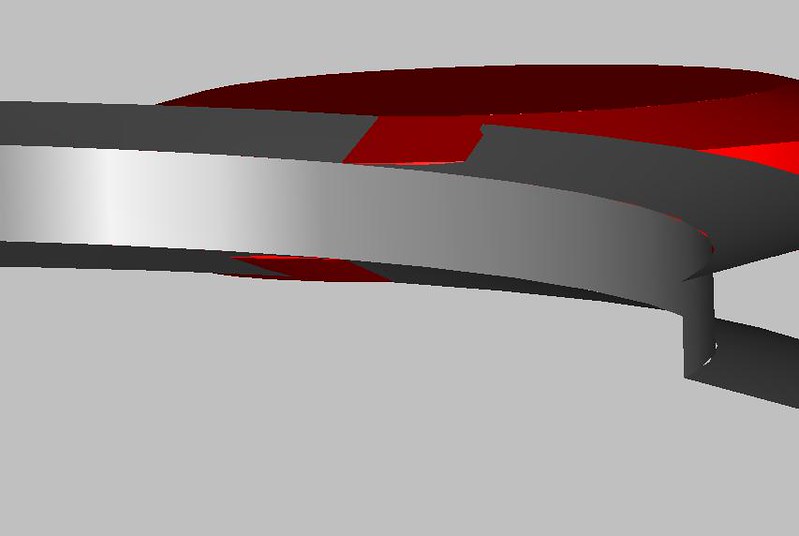

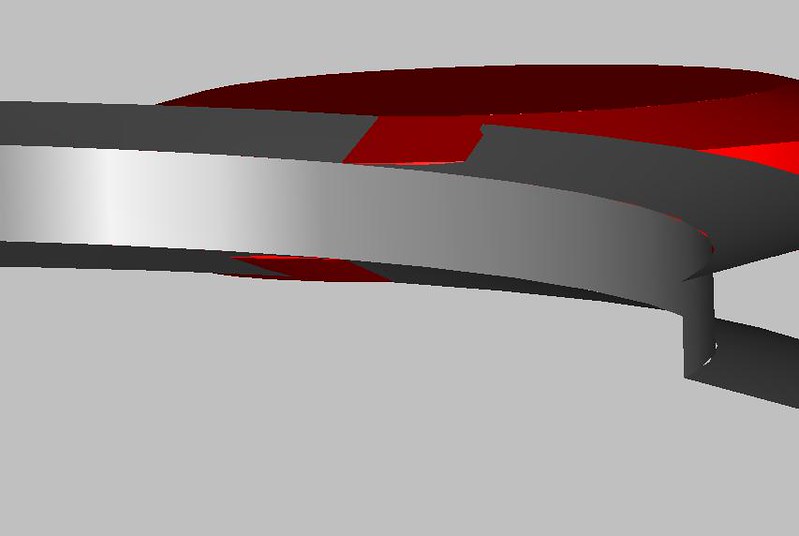

1"-5 2G internal they suggest this tool, doesn't appear to be an indexable though.

VARGUS GENius

You can also download an offline version.

1"-5 2G internal they suggest this tool, doesn't appear to be an indexable though.

VARGUS GENius

Vargus has an online software that tells you what tool to use, it's pretty slick.

You can also download an offline version.

1"-5 2G internal they suggest this tool, doesn't appear to be an indexable though.

View attachment 296273

VARGUS GENius

Thanks. I got an email back from Vargus saying "That is a no quote for us". It kind of confused me, being that there was no explanation.

Bobw

Diamond

- Joined

- Feb 8, 2005

- Location

- Hatch, NM Chile capital of the WORLD

Had to do, I believe it was a 1-5 many many years ago.

And then I started thinking about the threadmilling, and somebody,

it might be those guys up there sold a threadmill. So I just HAD

to draw it up to see if it was actually possible.

Its not, you blow out the entire thread form. Might as well just

use a key cutter, it'll do the same damn thing.

External, I think it would be possible to get an acceptable thread form,

internal, not a chance, unless it was a massive diameter, and an itty bitty

cutter.

Its just too steep, and the included angle is too narrow.

Get a tandem tap. If your machine doesn't have the nuts for driving it,

thread mill the form of the first section of the tandem tap(standard

single level threadmill), then it goes in nice and straight, and makes

your life a little easier.

And then I started thinking about the threadmilling, and somebody,

it might be those guys up there sold a threadmill. So I just HAD

to draw it up to see if it was actually possible.

Its not, you blow out the entire thread form. Might as well just

use a key cutter, it'll do the same damn thing.

External, I think it would be possible to get an acceptable thread form,

internal, not a chance, unless it was a massive diameter, and an itty bitty

cutter.

Its just too steep, and the included angle is too narrow.

Get a tandem tap. If your machine doesn't have the nuts for driving it,

thread mill the form of the first section of the tandem tap(standard

single level threadmill), then it goes in nice and straight, and makes

your life a little easier.

alphonso

Titanium

- Joined

- Feb 15, 2006

- Location

- Republic of Texas

Bobw is right in theory even though I have an ADVENT 5 pitch acme threadmill(S010558-BH3FAZ) that we successfully made some 1 x 5 nuts.

gregormarwick

Diamond

- Joined

- Feb 7, 2007

- Location

- Aberdeen, UK

Bobw is right in theory even though I have an ADVENT 5 pitch acme threadmill(S010558-BH3FAZ) that we successfully made some 1 x 5 nuts.

You ever check those nuts for proper threadform? Probably nothing stopping them from screwing on the mating part, they just won't have proper flank contact.

I've been through this long ago and came to the same conclusion as Bobw.

I just can't see any possible modified geometry that would generate the correct form, which leaves three options for the available to buy acme threadmills.

1. They have some compromised geometry that sort of kind of fudges a sort of kind of functional thread, or

2. The manufacturers of said threadmills don't care that their customers are going to make non-compliant threads, or

3. The manufacturers of said threadmills just ground the threadform without any checking of function and are unaware that their customers are going to make non-compliant threads.

Edit:

Fourth option, manufacturers of said threadmills have some fine print hidden away somewhere stating that 5 axis is required to use their threadmills.

1953chevB

Cast Iron

- Joined

- Jul 31, 2020

I don't remember but this may be able to tap, Had issues in the past with jobs like this.Vargus has an online software that tells you what tool to use, it's pretty slick.

You can also download an offline version.

1"-5 2G internal they suggest this tool, doesn't appear to be an indexable though.

View attachment 296273

VARGUS GENius

there was a supplier near Los Angeles USA , that would mfg the tap and go & no go gages, it's long shot

having a brain fart remembering the company name.

atex57

Stainless

- Joined

- Sep 6, 2006

- Location

- SW Wisconsin

OP, do you have rigid tapping? If so use a boring bar with the correct shape tool in a boring head. Tap, adjust tool out, tap, adjust, tap, etc. May not work with a carbide insert though, tool dragging on the way out.

Ed.

Ed.

alphonso

Titanium

- Joined

- Feb 15, 2006

- Location

- Republic of Texas

You ever check those nuts for proper threadform? Probably nothing stopping them from screwing on the mating part, they just won't have proper flank contact.

I've been through this long ago and came to the same conclusion as Bobw.

I just can't see any possible modified geometry that would generate the correct form, which leaves three options for the available to buy acme threadmills.

1. They have some compromised geometry that sort of kind of fudges a sort of kind of functional thread, or

2. The manufacturers of said threadmills don't care that their customers are going to make non-compliant threads, or

3. The manufacturers of said threadmills just ground the threadform without any checking of function and are unaware that their customers are going to make non-compliant threads.

Edit:

Fourth option, manufacturers of said threadmills have some fine print hidden away somewhere stating that 5 axis is required to use their threadmills.

We did cut a test piece in half and used a Topnotch insert to eyeball the shape. The form was screwed up(wide) at the crown of the thread for about .015". Looked kinda like a big chamfer. Put some Silly Putty in customer's sample and it showed the same non conformity. They haven't complained about it since put in service over a year ago.

Not sure if anything was decided here since the post got a little cold but no one has mentioned Carmex. They have a solid carbide thread mill for 5 pitch. I can't say for sure if it will work on a 1" but that is a pretty standard thread no? Would it not be designed to work for the most common use case?? We used one a while back because set up can be a pain in the ass on those taps since you need to go through the part by like 4". I believe it was a 1"-5. Think it took 2 passes. I didn't run it but I made the tool recommendation so I was somewhat familiar.

(edit)

Forgot to address the request for indexable. That to my knowledge doesn't exist but depending on your qty solid carbide will be the way to ge because you get a lot of flutes and more speed. Going to take forever with 1-2 flutes which is probably why no one has tackled the pain in the ass and highly niche task of making indexable at that size.

(edit)

Forgot to address the request for indexable. That to my knowledge doesn't exist but depending on your qty solid carbide will be the way to ge because you get a lot of flutes and more speed. Going to take forever with 1-2 flutes which is probably why no one has tackled the pain in the ass and highly niche task of making indexable at that size.

Similar threads

- Replies

- 5

- Views

- 447

- Replies

- 5

- Views

- 394

- Replies

- 23

- Views

- 2K