WakelessFoil

Aluminum

- Joined

- Aug 18, 2020

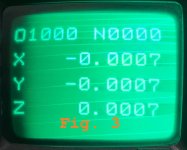

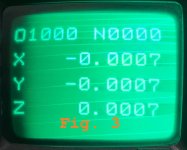

So I have been running some tests on our old Accumill to ensure it is ready for service in our shop. The latest hurtle that faces us relates to the incremental/absolute function. I have the control default parameter set to absolute mode (Fig. 1). From experience with out newer CNC machine, I would expect to see the actual location of each axis when the machine is first turned on. Instead the machine always boots up with all axis at 0.0000 as if the machine is still in incremental mode (Fig. 2). To temporarily combat this, I turn on the machine, perform a reference point return, reboot the machine, and perform another reference point return (to let the machine know it's at 0). At this point I am faced with another problem, after the last reference point return the axis do not read 0.0000 like I would expect, they read a couple ten thousandths off with pretty fair consistency (Fig. 3). Not sure if this is within tolerance for a machine of this age and nature, but I had to mention it.

Any input is greatly appreciated.

-Justin

Any input is greatly appreciated.

-Justin