Good afternoon everyone.

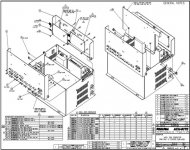

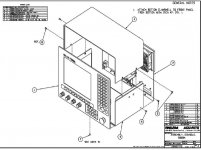

My 10-year-old knee-mill, it came from a college earlier this year so is little used and in very good condition, has developed an E-stop fault in the Anilam 5000M control. Initially, the 24v power supply went hi and ran 44v as the control signal, replaced it with a new one and I now have the correct voltage across the system. I have tracked the fault it down to the console and beyond that my skills aren't good enough to gain further insight into the fault.

I have asked a company in the USA about repair and I have been told I will need to send the control to them, I live in the UK, and it could cost $1000-3000 plus about $400 in postage/courier costs. If I deem it too expensive to repair it will still set me back $750-1250 plus postage.

As much as I like the control, I find it fairly intuitive and it has worked very well with Fusion 360 posts, it could well be far too expensive for me as a one-man band to have repaired, especially if it needs further work in the near future.

I thought to upgrade it to the Centroid Oak board and keep the Glentek SMA 9115-000-1-121B Amps and Acu-Rite HJ130-A8-44S AC brushless servos and add an inverter into the mix to give me spindle control. This still isn’t going to be particularly cheap, but it will at least give me an up to date controller that has a period of warranty. These items will work with the Oak without the need to fiddle with the servos.

Changing out the servos and drives to newer items is cost prohibitive.

Are there any other choices for controls for AC amps and servos and has anyone done this refit or similar - your advice and superior knowledge would be most welcome.

I do want to stay away from Linux, I don’t have the competencies to use it. I use Mach 4 on a lathe, but without the commercial variant it is lacking in some respects and I have no idea if there is a system to integrate it to run an AC system nor probably want to.

Many thanks.

My 10-year-old knee-mill, it came from a college earlier this year so is little used and in very good condition, has developed an E-stop fault in the Anilam 5000M control. Initially, the 24v power supply went hi and ran 44v as the control signal, replaced it with a new one and I now have the correct voltage across the system. I have tracked the fault it down to the console and beyond that my skills aren't good enough to gain further insight into the fault.

I have asked a company in the USA about repair and I have been told I will need to send the control to them, I live in the UK, and it could cost $1000-3000 plus about $400 in postage/courier costs. If I deem it too expensive to repair it will still set me back $750-1250 plus postage.

As much as I like the control, I find it fairly intuitive and it has worked very well with Fusion 360 posts, it could well be far too expensive for me as a one-man band to have repaired, especially if it needs further work in the near future.

I thought to upgrade it to the Centroid Oak board and keep the Glentek SMA 9115-000-1-121B Amps and Acu-Rite HJ130-A8-44S AC brushless servos and add an inverter into the mix to give me spindle control. This still isn’t going to be particularly cheap, but it will at least give me an up to date controller that has a period of warranty. These items will work with the Oak without the need to fiddle with the servos.

Changing out the servos and drives to newer items is cost prohibitive.

Are there any other choices for controls for AC amps and servos and has anyone done this refit or similar - your advice and superior knowledge would be most welcome.

I do want to stay away from Linux, I don’t have the competencies to use it. I use Mach 4 on a lathe, but without the commercial variant it is lacking in some respects and I have no idea if there is a system to integrate it to run an AC system nor probably want to.

Many thanks.