SigurdACVW

Aluminum

- Joined

- Aug 16, 2013

- Location

- IL

I've been on a Haas Minimill 2 and a 2D seat of Mastercam 2017 here at work for about a month. I have experience with Mastercam X5 and my Sharp 2-axis mill. I'm on my own for figuring out the programming of the Haas.

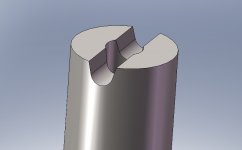

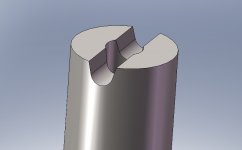

This is what I'm working on. It's a sprue bushing, part of an injection mold. I need to cut the angled walls (30 degrees included) and the .085" radius on the floor. The hole is already there. Ordinarily, I'd rough it out, then grab an 11/64 ballnose endmill to finish the radius and then make a 15 degree cutter on the Deckel and call it a day. Maybe put it all on one cutter. However, I'd like to try programming this time. I've been watching some videos on YouTube about the Swept 2D toolpath, but I can't seem to get it to work. It asks for the "across" contour, but never asks for the "along" contour, just "branch point reached". Would someone be willing to provide some guidance here? Thanks.

This is what I'm working on. It's a sprue bushing, part of an injection mold. I need to cut the angled walls (30 degrees included) and the .085" radius on the floor. The hole is already there. Ordinarily, I'd rough it out, then grab an 11/64 ballnose endmill to finish the radius and then make a 15 degree cutter on the Deckel and call it a day. Maybe put it all on one cutter. However, I'd like to try programming this time. I've been watching some videos on YouTube about the Swept 2D toolpath, but I can't seem to get it to work. It asks for the "across" contour, but never asks for the "along" contour, just "branch point reached". Would someone be willing to provide some guidance here? Thanks.