Bobw

Diamond

- Joined

- Feb 8, 2005

- Location

- Hatch, NM Chile capital of the WORLD

Hey All...

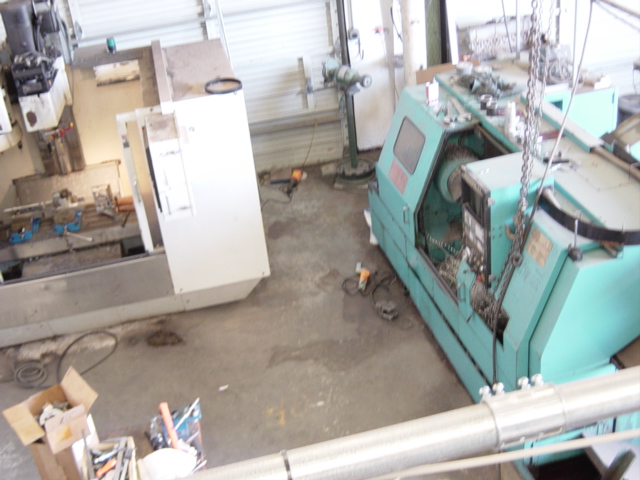

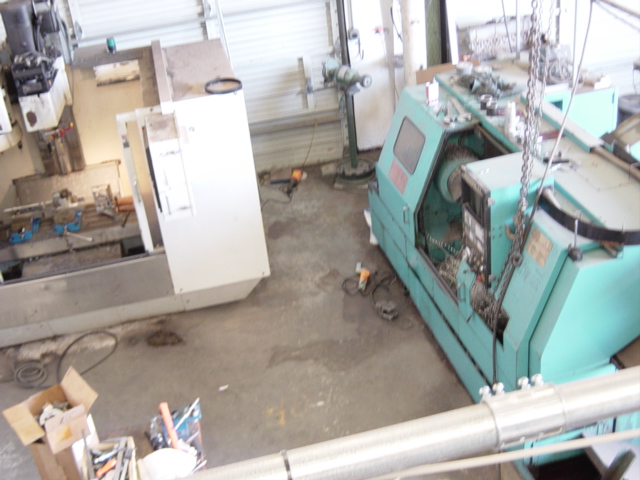

I need to throw some #'s on these machines and I have pretty much no clue where they are selling now.

First up.

'93 Fadal 4020.

extended 28" Z..

The normal stuff. 21 tools, 10k 2 speed 15/22.5hp spindle.

DC drives, does not have rigid tapping..

Plumbed for TSC but all the seals are shot.

Heavy scoring on the Z ways...

Yaskawa spindle drive.

Tool retention is really good,

X axis ball screw is pretty sloppy on the positive end. Pretty good everywhere else.

New Y axis motor.

Needs a new monitor.

Second up... '94 Fadal, same basic machine as above.. except its not plumbed for TSC,

this one also has a newer Yaskawa spindle drive and no rigid tapping.

4th axis.

This machine is tight, and clean (at least inside the cabinets).

Spindle is on its last legs.

Last up.

'84 Mazak QT20 the big one. 10" chuck, a bastard Howa that nobody will admit exists.

Its air, not hydraulic, so it has no drawtube. 3" through. (was 2.75 until I took a boring bar to it)

T1 control. 12 or 14" diameter on the X, a meter on the Z.

20hp continuous, 25 for 30minutes, 2 speed gear box, 3600 max rpm (I think its 3600)

She'll hold tenths all day long once she warms up. She'll drift off about .001 until

she warms up.

400 ipm rapids (if you can call that rapid)

Something wrong in the parameters, and even the tech couldn't figure it out. You can't

open and close the chuck with an M code, can't use the tailstock with an M code, and it

won't change gears automatically.

I just need some realistic $$ #'s to put on this stuff. So if you would all be so kind...

I'd appreciate it.

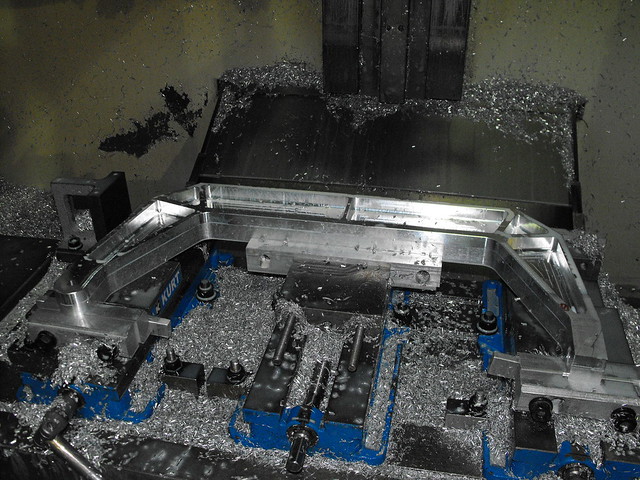

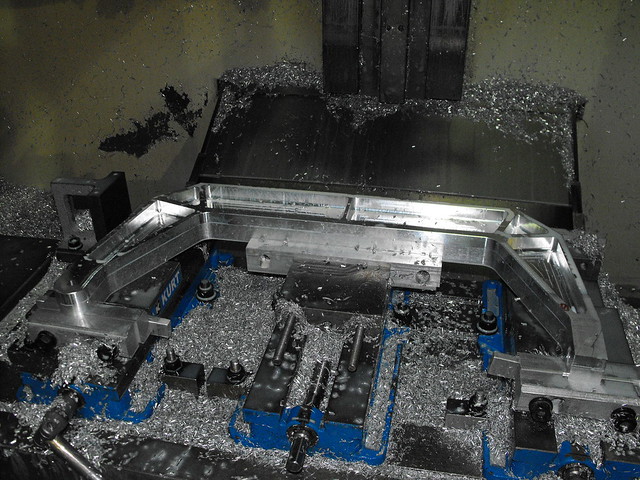

And just for fun... Here are those big giant C-clamps in action... Its always fun

when you get to see stuff you made in use.. If you can call holding a door open "action".

I need to throw some #'s on these machines and I have pretty much no clue where they are selling now.

First up.

'93 Fadal 4020.

extended 28" Z..

The normal stuff. 21 tools, 10k 2 speed 15/22.5hp spindle.

DC drives, does not have rigid tapping..

Plumbed for TSC but all the seals are shot.

Heavy scoring on the Z ways...

Yaskawa spindle drive.

Tool retention is really good,

X axis ball screw is pretty sloppy on the positive end. Pretty good everywhere else.

New Y axis motor.

Needs a new monitor.

Second up... '94 Fadal, same basic machine as above.. except its not plumbed for TSC,

this one also has a newer Yaskawa spindle drive and no rigid tapping.

4th axis.

This machine is tight, and clean (at least inside the cabinets).

Spindle is on its last legs.

Last up.

'84 Mazak QT20 the big one. 10" chuck, a bastard Howa that nobody will admit exists.

Its air, not hydraulic, so it has no drawtube. 3" through. (was 2.75 until I took a boring bar to it)

T1 control. 12 or 14" diameter on the X, a meter on the Z.

20hp continuous, 25 for 30minutes, 2 speed gear box, 3600 max rpm (I think its 3600)

She'll hold tenths all day long once she warms up. She'll drift off about .001 until

she warms up.

400 ipm rapids (if you can call that rapid)

Something wrong in the parameters, and even the tech couldn't figure it out. You can't

open and close the chuck with an M code, can't use the tailstock with an M code, and it

won't change gears automatically.

I just need some realistic $$ #'s to put on this stuff. So if you would all be so kind...

I'd appreciate it.

And just for fun... Here are those big giant C-clamps in action... Its always fun

when you get to see stuff you made in use.. If you can call holding a door open "action".