assface421

Aluminum

- Joined

- May 18, 2016

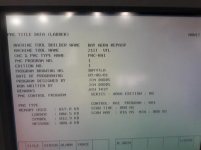

Hello everyone, My shop installed a "new" machine. Maintenance has been slow to get it going over the past few months. It is A Rafamet VTL CNC conversion. The table is 10'6" in diameter. The machine was built in 1966. The CNC Conversion was done in about 2008. It came with very little information. We have not figured out how to change gears. It is currently in low gear. The controller is saying the table is going way faster than it is in reality. Maintenance says they cant find any way of physically changing the gear. So it must be electronic on the controller. I have no Idea how that can be done. All of the other CNC's I have here have a physical lever. I have attached pictures for your enjoyment.

Any help would be greatly appreciated. Thank you for your time.

Any help would be greatly appreciated. Thank you for your time.