How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Circular milling a tapered hole

- Thread starter tyson333

- Start date

- Replies 19

- Views 6,231

Shop Supply Guru

Hot Rolled

- Joined

- May 3, 2016

- Location

- Ohio USA

Here we go

gustafson

Diamond

- Joined

- Sep 4, 2002

- Location

- People's Republic

What does your finish need to be?

I'm not gonna do the math, is it a particular taper?

i did a tapered off center[center of top was not same as center of bottom] hole on a bunch of parts for a friend years ago. Ball end mill, lots of coordinates, lousy finish

CAD/CAM is the way to do it

I'm not gonna do the math, is it a particular taper?

i did a tapered off center[center of top was not same as center of bottom] hole on a bunch of parts for a friend years ago. Ball end mill, lots of coordinates, lousy finish

CAD/CAM is the way to do it

Larry Dickman

Titanium

- Joined

- Jan 30, 2014

- Location

- Temecula, Ca

does it need to helix in the opposite direction in Australia?

Your description doesn't help much. Can you use a tapered end mill?

5 axis swarf cut?

Keller?

Your description doesn't help much. Can you use a tapered end mill?

5 axis swarf cut?

Keller?

G00 Proto

Hot Rolled

- Joined

- Feb 18, 2013

- Location

- Dirkdirkistan, ID

What does your finish need to be?

I'm not gonna do the math, is it a particular taper?

i did a tapered off center[center of top was not same as center of bottom] hole on a bunch of parts for a friend years ago. Ball end mill, lots of coordinates, lousy finish

CAD/CAM is the way to do it

What are you talking about... it's only three lines of code to make a tapered hole. Z -38.0, and A-10.0, and then a B 360.0

ChipSplitter

Titanium

- Joined

- May 23, 2019

- Location

- Maybe

solid carbide feedmill

really really fast feed

really light doc

like **** down the toilet........

really really fast feed

really light doc

like **** down the toilet........

gustafson

Diamond

- Joined

- Sep 4, 2002

- Location

- People's Republic

What are you talking about... it's only three lines of code to make a tapered hole. Z -38.0, and A-10.0, and then a B 360.0

not a vertical hole

ChipSplitter

Titanium

- Joined

- May 23, 2019

- Location

- Maybe

not a vertical hole

He's programming for a 5 axis machine.

spoiled kid.

gustafson

Diamond

- Joined

- Sep 4, 2002

- Location

- People's Republic

He's programming for a 5 axis machine.

spoiled kid.

huh?

2 1/2 axis machine

tapered hole, one side vertical.....

rorycollins0

Plastic

- Joined

- Apr 3, 2020

Given my experience if you are trying this in a three axes milling machine, and you need a finish better than a 120(not sure what that is in metric)your going to need to get a custom solid carbide tool made. First come in with an insert drill that will leave stock for the minor diameter. Next rough the taper in the hole with a ball mill by just stepping it down say .5mm or something, just doing simple circles with decreasing diameters. Than come in with the finish tool. if you have a lot of parts/holes you may want to get 2 finish mills, one to semi rough the part, the last to just kiss it and bring it in to tolerance. Be sure your grinder leaves enough flute on the tools to allow you to change your offsets without milling a straight/rubbing the shank as you get your setups dialed in.

I hope that is helpful.

Our shop makes some steering rack linkages assemblies that have taper holes in both faces(5 each part). Mat. is 4140 heat treat. We have done this on 1000s of them. They assemble like clockwork all day. Your nominal dimensions are really close to what were doing.

I hope that is helpful.

Our shop makes some steering rack linkages assemblies that have taper holes in both faces(5 each part). Mat. is 4140 heat treat. We have done this on 1000s of them. They assemble like clockwork all day. Your nominal dimensions are really close to what were doing.

ChipSplitter

Titanium

- Joined

- May 23, 2019

- Location

- Maybe

Given my experience if you are trying this in a three axes milling machine, and you need a finish better than a 120(not sure what that is in metric)your going to need to get a custom solid carbide tool made. First come in with an insert drill that will leave stock for the minor diameter. Next rough the taper in the hole with a ball mill by just stepping it down say .5mm or something, just doing simple circles with decreasing diameters. Than come in with the finish tool. if you have a lot of parts/holes you may want to get 2 finish mills, one to semi rough the part, the last to just kiss it and bring it in to tolerance. Be sure your grinder leaves enough flute on the tools to allow you to change your offsets without milling a straight/rubbing the shank as you get your setups dialed in.

I hope that is helpful.

Our shop makes some steering rack linkages assemblies that have taper holes in both faces(5 each part). Mat. is 4140 heat treat. We have done this on 1000s of them. They assemble like clockwork all day. Your nominal dimensions are really close to what were doing.

I agree.

If the OP is doing high production it puts it into a different realm altogether.

In that case a custom form tool would be the cat's meow.

BTW according to my calculations the angle would 6.75 deg.

angelw

Diamond

- Joined

- Sep 10, 2010

- Location

- Victoria Australia

They wont get a tool made as it is a one off

Hello tyson,

Following is a Basic Macro program to step mill the taper. Because its a "one off", I've pre-calculated the tool Z Start and Radius for the initial circle at Z Zero, rather than create the Macro Code to do so. This is based on the Bull Nosed End Mill with 2mm corner rads you specified. Any Bull Nose Cutter up to just under 17mm diameter can be used with the code as is; Tool Radius Comp has been included. I've also pre-calculated the Taper per Millimeter and included that as Hard Code in the program.

This is a Bare Bones example without any Error Trapping. You could develop the Macro more so that the Corner Radius of the cutter could be specified and have the Macro calculate the Z Start and Finish Levels.

You can edit the Z Increment Variable Value (#1) to modify the surface finish of the taper; the smaller the Z Increments, the finer the Surface Finish.

I have carried out a rough test and I can't see any obvious issues. However, as the Fanuc User Macro Application carries out calculations in Binary, there may be inherent errors in the calculation that may not have the DO LOOP end as expected. The program did perform as expected in all the tests I did using a multitude of different Z Increments.

The only issue will be that the calculated Final Z Value my be ever so slightly different to the #5 = -39.765 '(Z FINISH COORDINATE) used in the WHILE Statement and therefore, never tests Equal; only Less, or Greater Than. The result of this is that one extra Z Increment and cut cycle will be performed. There are "work arounds" for this:

1. After #3 = #3 + #1 (Z CUT LEVEL) is executed, perform a comparison to the Final Z (#5) and if #3 < #5, set #3 to the value of #5 in the following manner:

IF[#3 < #5] THEN #3=#5

However, its not quite as simple as just setting the Z Value (#3) to that of the required Z Final Value; you also need to calculate the Radius for that particular Level.

2. Subtract #3 from #5 and compare the result to an acceptable, small tolerance; 0.0001 for example. If the Result is <= to the tolerance, then #3 is deemed to be equal to #5 in the following manner and an Exit from the DO LOOP executed.

IF [[ABS[#5]]-[ABS[#3]] LE 0.0001] GOTO10

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

CODE

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

END1

N10

Example Macro Starts Here

(INITIALISE VARIABLES STARTS HERE)

#1 = -0.1 '(Z INCREMENT)

#2 = [0.11842 * #1] '(RADIAL DECREMENT)

#3 = -1.765 '(TRUE Z START COORDINATE)

#4 = 14.014 '(START COORDINATE RADIUS)

#5 = -39.765 '(Z FINISH COORDINATE)

#3 = #3 - #1 '(INITIAL Z START COORDINATE)

#4 = #4 - #2 '(RADIUS START VALUE)

G90 G00 X0.000 Y0.000

G00 Z10.0

G01 Z1.0 F1000

G01 Z#3 F500

(TOP CIRCLE STARTS HERE)

WHILE [#3 GE #5] DO1

#3 = #3 + #1 (Z CUT LEVEL)

#4 = #4 + #2 (CUT CIRCLE RADIUS)

G90 G01 Z#3 F500

G01 X5.514 Y0.000

G01 X[#4 - 8.5] Y0.000 (FEED TO CENTRE OF LEAD IN ARC)

G41 G01 X[#4 - 8.5] Y-8.500 D22 (APPLY TRC)

G03 X#4 Y0.000 I0.000 J8.500 (LEAD INTO CUT CIRCLE)

G03 X#4 Y0.000 I-#4 J0.000 (CUT CIRCLE)

G03 X[#4 - 8.5] Y8.500 I-8.500 J0.000 (LEADS OUT OF CUT CIRCLE)

G40 G01 X[#4 - 8.5] Y0.000

G91 G00 X-1.0

END1

G01 X0.000 Y0.000

G00 Z10.0

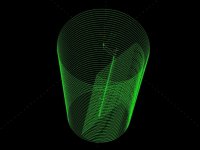

Following is the Graphic Back-plot resulting from the above Macro Program.

Regards,

Bill

Attachments

Last edited:

angelw

Diamond

- Joined

- Sep 10, 2010

- Location

- Victoria Australia

Had to take out that last g03 lead out of circle as the cutter was stepping in to the taper half way down. Now it works fine perfect finish running at 3300rpm f700 .perfect finish and not a single tool mark.

Hello tyson,

I'm not sure what you mean. Are you saying the Lead Out all the way down, or just at the last Z level? I can't see how that would, or could cause an issue. Following is the generated code for the last Z Level:

G41 G01 X1.014 Y-8.500 D22

G03 X9.514 Y0.000 I0.000 J8.500

G03 X9.514Y0.000 I-9.514 J0.000

G03 X1.014 Y8.500 I-8.500 J0.000

G40 G01 X1.014 Y0.000

As can be seen, the End of the Lead Out is a mirror image of the Start of the Lead In. Accordingly, if the Lead Out was an issue, so would be the move to the Start of the Lead In. The following picture is the Top View of the generated Tool Path. The Radius of the Lead Out Arc is 1.014mm less than the Cut Circle at the last Z Level and therefore, the centre of the Lead In, Lead Out arcs are on the plus side of the tapered bore's centre line.

Regards,

Bill

13engines

Stainless

- Joined

- Jun 30, 2015

- Location

- Saint Paul, MN

SaaaaaaaaWHOOOOOSH!!!

That's the sound of Bills' post #14 flying right over my head.

One of these days I gots to learn Macro B programming.

Dave

That's the sound of Bills' post #14 flying right over my head.

One of these days I gots to learn Macro B programming.

Dave

Scottl

Diamond

- Joined

- Nov 3, 2013

- Location

- Eastern Massachusetts, USA

Need help machining a tapered hole starting at 28mm dia tapering to 19 dia 38 deep. Am using fanuc 18i control and thinking macro or g code . Any sample will do. Cheers mick

A company I worked for did exactly that in castings before thread milling a large tapered pipe thread. They used a tapered end mill. When milling the thread they started at the bottom and spiraled out using circular interpolation with a ramp factor added. I do not know the details of the programming because I was in engineering, not the shop.

Hey bill

It was only starting to cut into the wall about a halfway down on approach of the first lead in so like i said once we took that last lead out of the arc it seem to fix it as well as the g01 x5.514 y0...i was guessing the small diameter to taper to as i was at home at the time apon posting this discussion acual taper was 28mm to 23.000.so i chanched the value #2=.0656167 .

It was only starting to cut into the wall about a halfway down on approach of the first lead in so like i said once we took that last lead out of the arc it seem to fix it as well as the g01 x5.514 y0...i was guessing the small diameter to taper to as i was at home at the time apon posting this discussion acual taper was 28mm to 23.000.so i chanched the value #2=.0656167 .

Similar threads

- Replies

- 18

- Views

- 1K