Good day to all.

I have managed to setup and connect a CNC mill machine (Mitsubishi Meldas 60) to a PC.

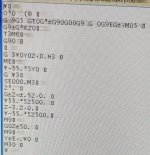

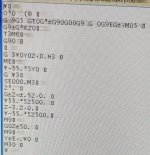

When i am sending a program from PC to CNC everything is ok, but when i am sending from CNC to PC the transferred program either missing spaces and characters (Pic.01) or some characters are altered (Pic.02).

In the pictures you can see a very simple program. I i wrote it and sent to CNC and then tried to get it back to PC.

I have tried:

- To change many parameters mainly in output

- Tried 2-3 DNC free software and 2 different PCs

- Tried to change handshake

- Tried to change the port settings and the FIFO

I also checked the wiring of the 9pin/25pin RS232.

Any ideas what else to try?

Thank you in advance.

I have managed to setup and connect a CNC mill machine (Mitsubishi Meldas 60) to a PC.

When i am sending a program from PC to CNC everything is ok, but when i am sending from CNC to PC the transferred program either missing spaces and characters (Pic.01) or some characters are altered (Pic.02).

In the pictures you can see a very simple program. I i wrote it and sent to CNC and then tried to get it back to PC.

I have tried:

- To change many parameters mainly in output

- Tried 2-3 DNC free software and 2 different PCs

- Tried to change handshake

- Tried to change the port settings and the FIFO

I also checked the wiring of the 9pin/25pin RS232.

Any ideas what else to try?

Thank you in advance.