Houdini

Titanium

- Joined

- Nov 28, 2017

Quick question.

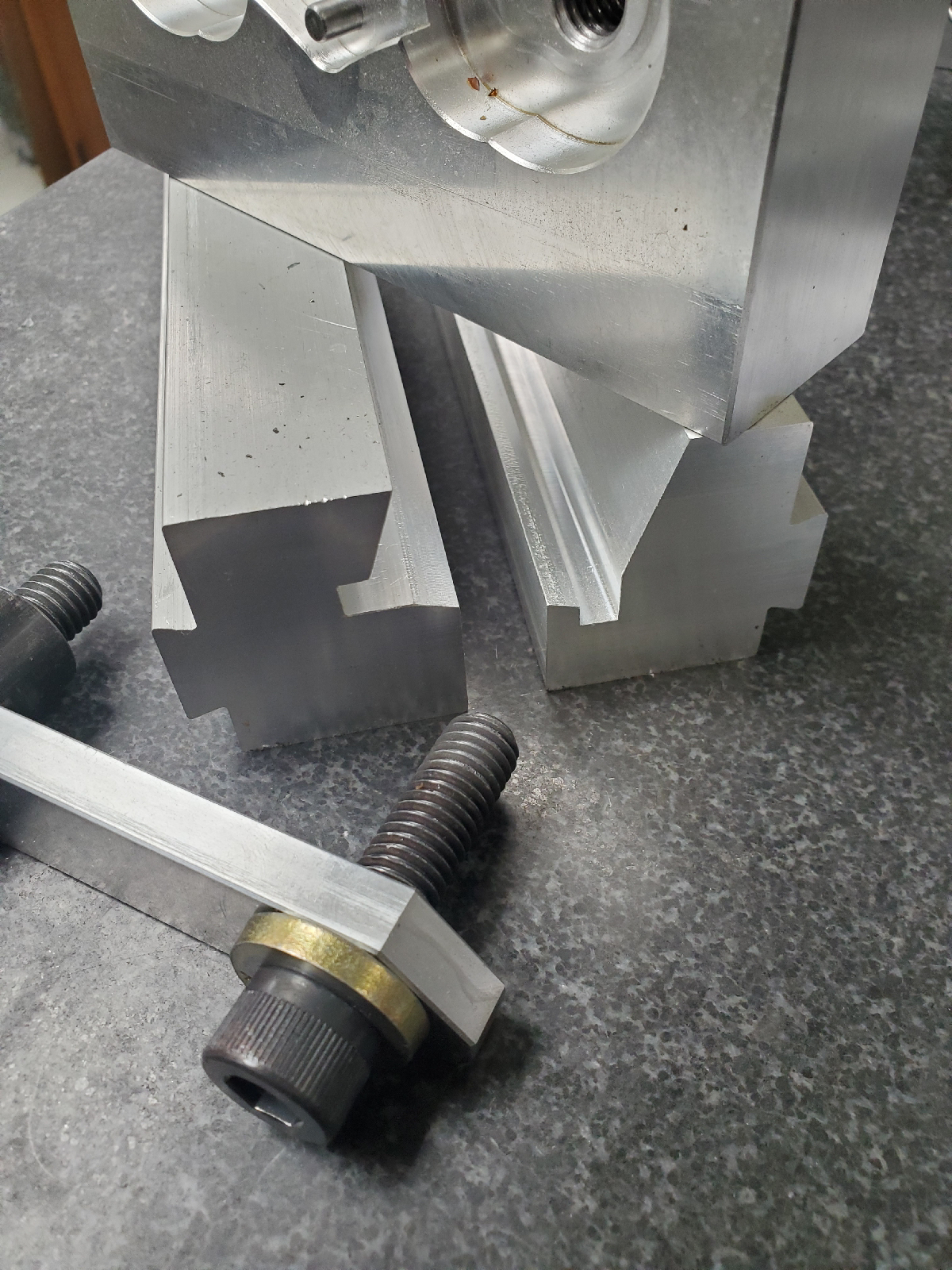

In my 15 years I haven't had to machine any compound angle parts, that actually needed to be held at that angles due to a tapped hole.

Any tricks to save me time?

We use double station orange vises, these are 120 part per month orders, So not a one off.

Would like to make work holding in jaws if possible?

More heads are better than 1! Ideas?

In my 15 years I haven't had to machine any compound angle parts, that actually needed to be held at that angles due to a tapped hole.

Any tricks to save me time?

We use double station orange vises, these are 120 part per month orders, So not a one off.

Would like to make work holding in jaws if possible?

More heads are better than 1! Ideas?