Anyone have any ideas, tips, tricks or accessories that they would like to share?

I've been doing a lot of horizontal programming for parts that we are trying to reduce cycle time and consolidate operations for parts that are increasing in volume and currently run on VMC's or on tombstones but require 1 or 2 refixturing steps to hit all sides of the part.

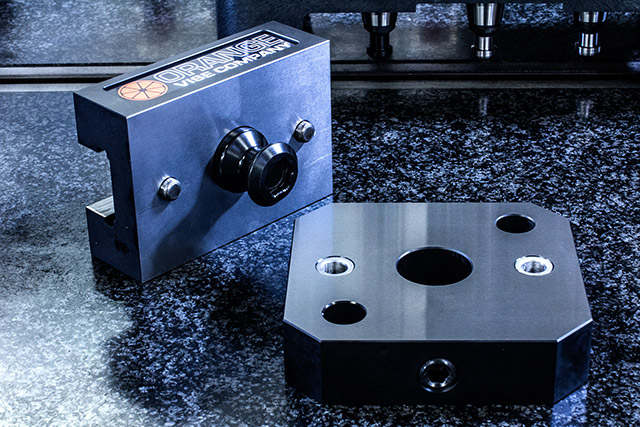

Some of them justify the investment in high-zoot tooling/fixturing. I'm open to everything from KME rotary indexers that mount on tombstones to automatic hydraulic/pneumatic clamping that is activated by M-codes, to (my dream) something simpler than a KME that would easily/quickly either index a part 90 degrees or flip it over and re-clamp. I know I could use a robot for that sort of thing, but looking for something that can live on a tombstone dedicated for that part.

Lots of creative minds here... what say you?

I've been doing a lot of horizontal programming for parts that we are trying to reduce cycle time and consolidate operations for parts that are increasing in volume and currently run on VMC's or on tombstones but require 1 or 2 refixturing steps to hit all sides of the part.

Some of them justify the investment in high-zoot tooling/fixturing. I'm open to everything from KME rotary indexers that mount on tombstones to automatic hydraulic/pneumatic clamping that is activated by M-codes, to (my dream) something simpler than a KME that would easily/quickly either index a part 90 degrees or flip it over and re-clamp. I know I could use a robot for that sort of thing, but looking for something that can live on a tombstone dedicated for that part.

Lots of creative minds here... what say you?