Thomas.Sears

Plastic

- Joined

- Jul 19, 2019

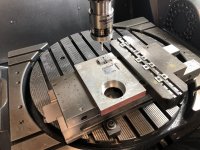

For over 2 years we had been struggling to get consistent accuracy out of our DMU 50 machines when the table swiveled to extreme angles in Cycle 800 ie. B90 C90. Turns out we had been setting the offsets incorrectly. When using the "Align Edge" probing cycle, there are 2 different options on how to store your offset: "Rot B/C axis" and "Coordinate Rot." If your program is using Cycle 800 to swivel, YOU MUST STORE YOUR ANGLES IN COORDINATE ROT and leave the numerical B and C work offset at 0. You must go to the "details" page under work offsets to see the rotational values. After you have set the rotational offsets you must call up a cycle 800 with 0s in the rotation and transformation values for the machine to level the part. Then you can correctly probe X, Y, and Z while the cycle is still active.

We had been setting the offsets in the regular B and C work offsets, causing mass confusion and headache on why our machine couldn't position correctly. Hope this helps out anyone else with accuracy issues on Siemens DMU machines! If you use them right they're pretty accurate!

We had been setting the offsets in the regular B and C work offsets, causing mass confusion and headache on why our machine couldn't position correctly. Hope this helps out anyone else with accuracy issues on Siemens DMU machines! If you use them right they're pretty accurate!