CNC Farming

Aluminum

- Joined

- Sep 2, 2017

Fanuc 11ma blank screen... HELP Please

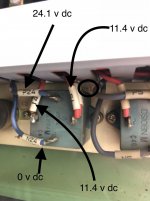

Hey guys, I fired up old Mori(MV-80) earlier today and everything was fine. Homed the machine, moved to table so I could reach the spindle to swap out tools manually because the one in it is to heavy for the tool changer, switched tools and went to type m06 for the tool changer to switch to the tool I wanted but the screen was blank. Now it wont show anything. It started acting up a few weeks ago, sometimes it would take longer for the screen to come on after the hydraulics started up, one time it started flashing/ moving the text around the screen but then it worked like normal and one time I had the screen working fine but had no lights like the ATC HP,TLC,MEM or ZRN etc. a shut down and restart fixed that. But today I have no screen...Everything else seems to work except the display. Can anyone point me in the right direction on what to check? PS the error light is on because I didn't start the air compressor up tonight just to check if the screen would work.

Hey guys, I fired up old Mori(MV-80) earlier today and everything was fine. Homed the machine, moved to table so I could reach the spindle to swap out tools manually because the one in it is to heavy for the tool changer, switched tools and went to type m06 for the tool changer to switch to the tool I wanted but the screen was blank. Now it wont show anything. It started acting up a few weeks ago, sometimes it would take longer for the screen to come on after the hydraulics started up, one time it started flashing/ moving the text around the screen but then it worked like normal and one time I had the screen working fine but had no lights like the ATC HP,TLC,MEM or ZRN etc. a shut down and restart fixed that. But today I have no screen...Everything else seems to work except the display. Can anyone point me in the right direction on what to check? PS the error light is on because I didn't start the air compressor up tonight just to check if the screen would work.

Attachments

Last edited: