thunderskunk

Cast Iron

- Joined

- Nov 13, 2018

- Location

- Middle-of-nowhere

Hey folks,

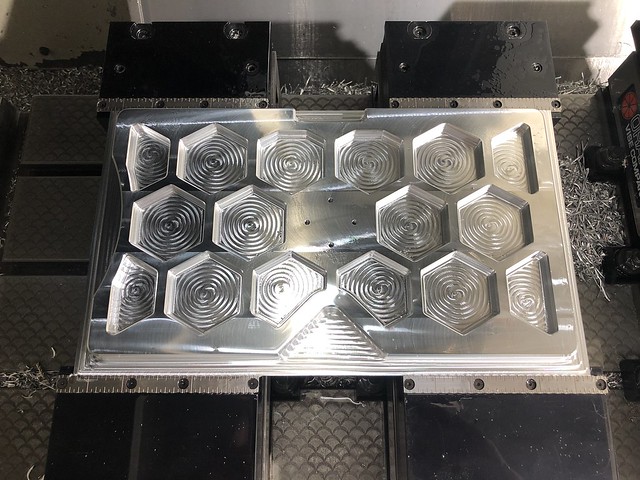

I’ve learned a lot picking your brains about quick change fixtures. So far I’ve been scoffing at orange vise as a gimmick product, but they caught my eye so I took a second look. The concept is pretty stinkin novel with the built in mitee bites, dovetail jaws, v groove pallets, locating ball locks, etc.

I know there’s a fella here from orange vise as well, I’m sure he’ll chime in. What’s the overall impression on them? Huge time saver or just a minor convenience?

I’ve learned a lot picking your brains about quick change fixtures. So far I’ve been scoffing at orange vise as a gimmick product, but they caught my eye so I took a second look. The concept is pretty stinkin novel with the built in mitee bites, dovetail jaws, v groove pallets, locating ball locks, etc.

I know there’s a fella here from orange vise as well, I’m sure he’ll chime in. What’s the overall impression on them? Huge time saver or just a minor convenience?

.

.