HappyHapgood

Plastic

- Joined

- Nov 28, 2020

I am a beginner and I've searched high and low for how to resolve this challenge. Any help would be appreciated.

I'm actually excited, because last night I machined my first part based on a Fusion360 program. It was fairly simple but worked as expected. But on to my challenge...

I am using Fusion 360 and trying to make a fairly simple part. The part is the same length as my soft jaws, so I planned to face the top and then mill off each end of the stock right up to the soft jaws.

Problem is that I can't find any way in Fusion360 to mill off those ends without a tool path that curves into the stock from "inside" and thereby mill into the soft jaws. I've tried lead-in angles, I've tried making sketches and solid bodies that "stock contours" should protect. But nothing works. And as a beginner its especially challenging because each strategy seems to suggest a different theory for how to protect areas. Actually, I'm also confused why some of the strategies want to mill stock from the sides that are already perfectly sized (and sitting in the soft jaws.

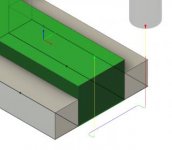

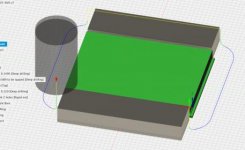

Here's a screenshot that shows how the tool wants to curve into the stock. The "grey" parts on the top and bottom are extra bodies that I created to try to get the stock contours to avoid.

Any suggestions? Which strategy would work best? Specifics on setup? FYI, the stock and the vice soft jaws are exactly 3" long. The stock is already perfectly sized at 2.25" (manually faced down to get proper size) and the height of the stock is 0.31 that will be faced down to 0.25 (taking some off in first op and down to 0.25" in second op).

Thanks for any help!

Matt

I'm actually excited, because last night I machined my first part based on a Fusion360 program. It was fairly simple but worked as expected. But on to my challenge...

I am using Fusion 360 and trying to make a fairly simple part. The part is the same length as my soft jaws, so I planned to face the top and then mill off each end of the stock right up to the soft jaws.

Problem is that I can't find any way in Fusion360 to mill off those ends without a tool path that curves into the stock from "inside" and thereby mill into the soft jaws. I've tried lead-in angles, I've tried making sketches and solid bodies that "stock contours" should protect. But nothing works. And as a beginner its especially challenging because each strategy seems to suggest a different theory for how to protect areas. Actually, I'm also confused why some of the strategies want to mill stock from the sides that are already perfectly sized (and sitting in the soft jaws.

Here's a screenshot that shows how the tool wants to curve into the stock. The "grey" parts on the top and bottom are extra bodies that I created to try to get the stock contours to avoid.

Any suggestions? Which strategy would work best? Specifics on setup? FYI, the stock and the vice soft jaws are exactly 3" long. The stock is already perfectly sized at 2.25" (manually faced down to get proper size) and the height of the stock is 0.31 that will be faced down to 0.25 (taking some off in first op and down to 0.25" in second op).

Thanks for any help!

Matt