13engines

Stainless

- Joined

- Jun 30, 2015

- Location

- Saint Paul, MN

Crash! UPDATE: Mori SV-50 finds weak spot in Komet ABS50 Connection

Hi All,

Well the true reason for the drill failure just showed it's face. A left over Z-0.2800 in my G54P10 work offset for the 8th station on the 2nd pallet. (16th part as mentioned) I had run a G10 clearing program to clear out old offsets but obviously missed the Z there.

I reprogrammed the part to use a 3/4 carbide end mill to helical out the entire bore. First move was 0.28 into the part. The tool was spinning fast and managed the plunge, but it showed me the real reason for the drill crash. This also explains the odd tool marks on the damaged stock. Really didn't make sense until now.

Anyway... a veeerrry expensive left over Z offset. Sheeeeye*t!

Dave

Thought I'd share a misfortune I had this afternoon. Not sure if the outer insert failed first or the stock moved. Didn't even throw an alarm. Spindle still sounds fine as always. Drilling through the middle of two parts clamped in a vise. This was the 16th set. I imagine the drill saw this as an interrupted cut. It was sounding like it, and different then when drilling through a single solid in the past. This was a 1.77" clearance hole that had a 3/4 end mill following that brought it out to 2".

I love these Komet Trigon drills. Was always wondering where the weak link was and I guess I found it. Curious if anyone else has had extended success in drilling clamped parts like this with this type of drill. I really wish I new what gave way as I'd like to use this type of clamped work drilling again in the future. The stock had been previously faced on the faces touching the vise jaws leaving the mating surfaces as delivered. Not the best scenario for sure.

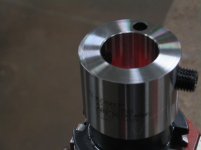

It trashed the holder too creating a 0.003-0.004 gap on the outer edge in one spot and a little mushroom on the bore edge. I have about $625.00 in this drill/holder setup. The holder is practically brand new. Ouch!

Live and learn? Wish I had it in slow-mo to see what happened.

Dave

Hi All,

Well the true reason for the drill failure just showed it's face. A left over Z-0.2800 in my G54P10 work offset for the 8th station on the 2nd pallet. (16th part as mentioned) I had run a G10 clearing program to clear out old offsets but obviously missed the Z there.

I reprogrammed the part to use a 3/4 carbide end mill to helical out the entire bore. First move was 0.28 into the part. The tool was spinning fast and managed the plunge, but it showed me the real reason for the drill crash. This also explains the odd tool marks on the damaged stock. Really didn't make sense until now.

Anyway... a veeerrry expensive left over Z offset. Sheeeeye*t!

Dave

Thought I'd share a misfortune I had this afternoon. Not sure if the outer insert failed first or the stock moved. Didn't even throw an alarm. Spindle still sounds fine as always. Drilling through the middle of two parts clamped in a vise. This was the 16th set. I imagine the drill saw this as an interrupted cut. It was sounding like it, and different then when drilling through a single solid in the past. This was a 1.77" clearance hole that had a 3/4 end mill following that brought it out to 2".

I love these Komet Trigon drills. Was always wondering where the weak link was and I guess I found it. Curious if anyone else has had extended success in drilling clamped parts like this with this type of drill. I really wish I new what gave way as I'd like to use this type of clamped work drilling again in the future. The stock had been previously faced on the faces touching the vise jaws leaving the mating surfaces as delivered. Not the best scenario for sure.

It trashed the holder too creating a 0.003-0.004 gap on the outer edge in one spot and a little mushroom on the bore edge. I have about $625.00 in this drill/holder setup. The holder is practically brand new. Ouch!

Live and learn? Wish I had it in slow-mo to see what happened.

Dave

Attachments

Last edited: