pmanoj

Plastic

- Joined

- May 27, 2013

- Location

- https://t.me/pump_upp

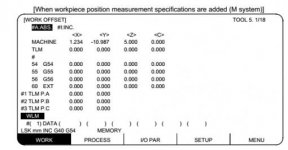

Hello. I use Paratec PV5 machining center with Mitsubishi Meldas 60 controller.* After I set Z value of the surface, tool length, and offset tool and started the operation.* The Z value shown in the position page does not equal to zero when the tip of the tool touched the surface of workpiece.* *It seems like G43 did not execute properly. What is wrong with G43 and how can I fix it?* Thank you.