BS!

No straight plunge on a thread or it will never be correct!

Somehow Haas figured it out a bit over 20 years ago. Nowadays it just might be high time for Fanuc to do the same!

Finish pass from Start-End in X and Z should always be in the very same position regardless G76 or G92 otherwise the thread is fucked up!

In what manner are the Haas Threading cycles different to the Fanuc? Following are extracts from the Haas programming Manual with the corresponding extract from a Fanuc Manual.

From Haas Manual

G92 Threading Cycle

F(E) Feed rate, the lead of the thread

I Optional distance and direction of X axis taper, radius

Q Start Thread Angle

U X-axis incremental distance to target, diameter

W Z-axis incremental distance to target

X X-axis absolute location of target

Z Z-axis absolute location of target

Chamfering on retract at the End of Thread can be set with Settings 95 and Setting 96. Chamfering is turned On/Off with M23 and M34 respectively.

From Fanuc Manual

G92 Threading Cycle

G92X(U)__ Z(W)__ R__ F__ ; Lead (L) is specified.

X Absolute X-axis target value

Z Absolute Z-axis target value

U Incremental X-axis target distance - diameter

W Incremental Z-axis target distance

R Distance and direction of X axis taper - radius value

Q Start Thread Angle – Describes Start Angle for Multi Lead Threads

F Feed rate

Chamfering distance is specified in a range from 0.1L

to 12.7L in 0.1L increments by parameter (parameter number is control model specific but parameter 5130 applies for controls from around FS15 on)

From Haas Manual

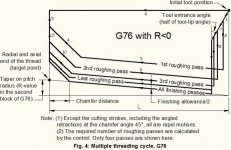

G76 Threading Cycle, Multiple Pass

A Tool nose angle (value: 0 to 120 degrees) Do not use a decimal point

D First pass cutting depth

F(E) Feed rate, the lead of the thread

I Thread taper amount, radius measure

K Thread height, defi nes thread depth, radius measure

P Thread Cutting Method P1-P4

Q Thread Start Angle (Do not use a decimal point)

U X-axis incremental distance, start to maximum thread Depth Diameter

W Z-axis incremental distance, start to maximum thread length

X X-axis absolute location, maximum thread Depth Diameter

Z Z-axis absolute location, maximum thread length

Chamfering on retract at the End of Thread can be set with Settings 95 and Setting 96. Chamfering is turned On/Off with M23 and M34 respectively.

Fanuc Two Block Cycle, referred to as FS16 Standard Format

G76P (m) (r) (a) Q (d min) R(d);

G76X (u) _ Z(W) _ R(i) P(k) Q(d) F(L) ;

m = Repetitive count in finishing (1 to 99)

r = Chamfering amount

a = Angle of tool tip

One of six kinds of angle, 80°, 60°, 55°, 30°, 29°, and 0°, can be selected,

and specified by 2–digit number.

Q (d min) = Minimum cutting depth (specified by the radius value)

R(d) = Finishing allowance

R(i) = Difference of thread radius radius If i = 0, ordinary straight thread cutting can be made.

If i is omitted I = 0 is assumed

P(k) = Height of thread. This value is specified by the radius value.

Q(d) = Depth of cut in 1st cut (radius value)

L = Lead of thread (same as G32).

Fanuc controls that use FS16 Standard Format can also be set via parameter to use Single Block Multi-repetitive Cycles, referred to as FS15 Format. The exception to this is the circa late 80’s FSO control.

The Fanuc Single Block G76 (FS15 Format) is the same as the Haas G76 cycle.

Unless the Haas G92 Cycle has been changed in recent time and I’ve not become aware of it, this cycle has no function to specify a Thread Profile Angle (Tool Tip Angle) and therefore, each successive cut will be made by the tool advancing in the X axis only. With the Haas (and Fanuc) G76 cycle, a Tool Tip Angle can be specified to have the tool cut with the Leading Edge of the insert.

There are two ways in which the Specified angle can be applied:

1. By calculation a minute shift in the Z Start Point (same method described by Sinha)

2. By applying an Index Angle for each Thread Pass. This in essence is cutting a Multi-lead Thread where the Thread Pitch is equal to amount of shift required to have the Trailing Edge of the Threading tool just kiss the Trailing Thread Flank.

In either case, the position of the Thread Groove relative to the original Z Start will be shifting as the Threading Process continues.

The Fanuc control performs a shift of the Z Start with each Thread Pass if a Tip Angle other than Zero is specified. If you observe the movement of the tool closely at the start of each Thread Pass, you will see this happen. However, the tool always returns to the original Z Start coordinate at the end of each Thread Pass.

The above being so, the only way I can see a G92 Threading Cycle being able to track precisely in the Thread Groove previously cut using a G76 Cycle and where a Tool Tip Angle other than Zero was specified, is if the Tool didn’t return to the original Z Start coordinate, but to a coordinate that equates to the shift required to have the Leading Edge of the Tool cut in accordance with the Tool Tip Angle specified.

I’m unsure if the Haas returns to the original Z Start Coordinate after every Thread Pass. If it were the case that it returned to the Offset Z Start and the G92 cycle was executed immediately from the Offset Z Start, then I can see that the Tool will track the last Threading Pass made by the G76 cycle. However, if the original Z Start for the G76 Cycle with a Tool Tip angle specified was, say, Z10.0 (mm) and a G92 Cycle was subsequently executed from the same Z Start, I fail to see how it would track precisely in the same Thread Groove as the G76 Cycle's final pass.

A very simple method to take further passes at finish DOC on a Thread cut using the G76 cycle, is to execute another G76 Cycle with the First Threading Pass value the same as the Thread Height specified in the cycle. All other parameters of the Thread should not be changed. This will result in a single threading pass at full depth and will precisely track the Thread Groove previously cut with the G76 Cycle.

Regards,

Bill

i am not a Fanuc guy, but i think that G76 targets a cycle, while G92 targets single syncro passes

i am not a Fanuc guy, but i think that G76 targets a cycle, while G92 targets single syncro passes