Honestly the best advise you can get!

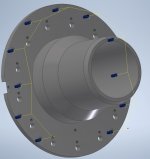

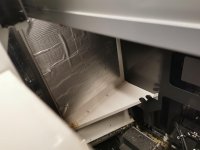

Right out of the gate, the BMT turret provides far better clearance than any other turret, bar none.

The standard VDI and the BOT would be in your way even on a collet chuck, never mind a 3 jaw chuck, and it will be in your way EVERY FRIGGIN' TIME!!!

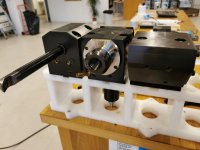

The BMT turret is an industry standard and as such it has the best variety of available tool blocks, let it be live or static tools.

What that also means is that if in the future you get a Mori or Doosan or whatever with the 65 turret, you can use the same toolblocks on them.

Third ( and I am just thinking out loud here ), the BMT turret is far more massive than any other, which means you will have much more mass behind your cutting tool.

Certainly a positive when it comes to a Haas!