How do you make machined delrin not look like poop? <SOLVED: Use new cutters>

I'm trying to machine some delrin and am struggling to get a nice surface finish. Side-milling works fine, but I cant figure out how to face it well.

It leaves little fuzzies and isnt nice and smooth like aluminum. It also seems like the chips dont really want to break.

Here is what Ive tried

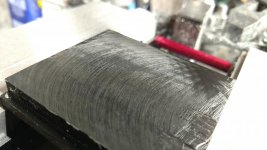

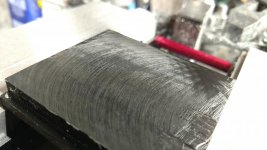

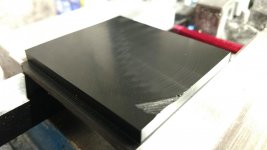

1: Tormach Super fly - 3in fly cutter

9in/min, 10thou DOC, 3thou feed/tooth (ignore right side, didnt cut deep enough to get rid of saw marks)

IMG_20211202_193434877.jpg

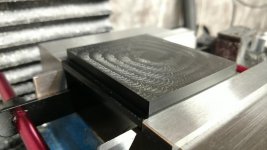

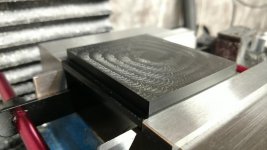

HSS 4flute 1/2in endmill

36in/min, 20thou DOC, 3thou feed/tooth

You can see the sides turned out fine with side-milling, just not the face

IMG_20211202_175245114.jpg

IMG_20211202_175400174.jpg

Also I am not using any kind of coolant/ fluid, should I be? my thought was no since its plastic, but what do i know

Thoughts?

I'm trying to machine some delrin and am struggling to get a nice surface finish. Side-milling works fine, but I cant figure out how to face it well.

It leaves little fuzzies and isnt nice and smooth like aluminum. It also seems like the chips dont really want to break.

Here is what Ive tried

1: Tormach Super fly - 3in fly cutter

9in/min, 10thou DOC, 3thou feed/tooth (ignore right side, didnt cut deep enough to get rid of saw marks)

IMG_20211202_193434877.jpg

HSS 4flute 1/2in endmill

36in/min, 20thou DOC, 3thou feed/tooth

You can see the sides turned out fine with side-milling, just not the face

IMG_20211202_175245114.jpg

IMG_20211202_175400174.jpg

Also I am not using any kind of coolant/ fluid, should I be? my thought was no since its plastic, but what do i know

Thoughts?

Last edited:

Wait till you try a used tool on UHMW, WAY less forgiving then delrin.

Wait till you try a used tool on UHMW, WAY less forgiving then delrin.