How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How would I cut/ hollow this part out?

- Thread starter pizza654

- Start date

- Replies 29

- Views 3,918

Larry Dickman

Titanium

- Joined

- Jan 30, 2014

- Location

- Temecula, Ca

Let me guess. You're a student and you need someone to do your homework for you.

I'd use a Dremel.

I'd use a Dremel.

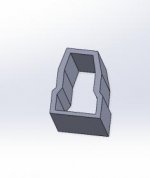

How would I turn a part like this

View attachment 335085

And hollow it out into something like this?

View attachment 335086

the dimensions are

150mm long, 40mm wide and 50mm tall

Any advice would be much appreciated thank you!

Here you go:

https://images-na.ssl-images-amazon.com/images/I/91IIE9dxl4L._SL1500_.jpg

trochoidalpath

Cast Iron

- Joined

- Jan 17, 2016

Wire EDM or a broach, if those interior corners have to be square. If you need a lot, talk to someone about getting it as an extrusion.

WOW! Funny, you should be a comedian!

...and you should stick with your "Day Job"....

David Ferguson

Cast Iron

- Joined

- Aug 13, 2008

- Location

- Paso Robles, CA

No but, you could machine it in two parts, and then bolt/weld/glue them together. You don't mention the material. This might be a good part for 3D printing.

mhajicek

Diamond

- Joined

- May 11, 2017

- Location

- Maple Grove, MN, USA

How would you turn a part like that? You wouldn't. Turning means making it on a lathe, which makes round parts.

To make such a part however, in large quantity, extrusion. Otherwise, wire EDM. Yes, these processes are expensive, which is why people that know better avoid sharp inside corners.

It could be done by a combination of milling and broaching, but that would be a real pain IMO.

To make such a part however, in large quantity, extrusion. Otherwise, wire EDM. Yes, these processes are expensive, which is why people that know better avoid sharp inside corners.

It could be done by a combination of milling and broaching, but that would be a real pain IMO.

LKeithR

Stainless

- Joined

- Sep 1, 2011

- Location

- Langley, B.C.

...but I don't actually need the part, I was just curious if could be done on a cnc mill but by the looks of it I guess not

Isn't that pretty much what Doug suggested? Just an imaginary part.

I suppose, it it were a one-off, that it could be done on a shaper. Take an over-size piece of stock

and bore out the largest possible hole that would fit within the profile then attack it with a shaper.

You'd need to to rotate the part several times and you'd likely need to grind multiple tools but it

could be done. Once you had the ID finished you could whittle away at the outside with a regular

mill.

You could also do the inside with a wire EDM but that would be a long, slow process...

mhajicek

Diamond

- Joined

- May 11, 2017

- Location

- Maple Grove, MN, USA

You could also do the inside with a wire EDM but that would be a long, slow process...

Compared to making it on a shaper, requiring several custom ground tools?

We don't know the scale of the part. Could be three feet across, or 3mm. If the former, maybe start with a casting. If the latter, maybe have it lasered.

Isn't that pretty much what Doug suggested? Just an imaginary part.

I suppose, it it were a one-off, that it could be done on a shaper. Take an over-size piece of stock

and bore out the largest possible hole that would fit within the profile then attack it with a shaper.

You'd need to to rotate the part several times and you'd likely need to grind multiple tools but it

could be done. Once you had the ID finished you could whittle away at the outside with a regular

mill.

You could also do the inside with a wire EDM but that would be a long, slow process...

No indication of material....could be non-conductive....Like "Play Doh !"

but is their no possible way to manually mill out the inside?

Not if you need those inside corners sharp (90 degrees).

How would I turn a part like this

View attachment 335085

And hollow it out into something like this?

View attachment 335086

the dimensions are

150mm long, 40mm wide and 50mm tall

Any advice would be much appreciated thank you!

For Pasta Lovers Bored By Spaghetti, There's A New Short, Wavy, Sauce-Holding Shape : NPR

MaxPrairie

Hot Rolled

- Joined

- Jul 9, 2015

Yes it is possible and no it would not be fun.

Scottl

Diamond

- Joined

- Nov 3, 2013

- Location

- Eastern Massachusetts, USA

No actually, I'm a novice and I just started doing machining as a hobby. Genuinely curious if this can actually be done on a cnc mill like a tormach

NO! There is no way to mill those sharp internal corners.

Old technology: Metal Shaper

New technology: Wire EDM

MaxPrairie

Hot Rolled

- Joined

- Jul 9, 2015

Typically, if this were an aluminum part and there were a lot of them to make a guy would make a custom extrusion die and make them 12 feet long then cut to length.

Similar threads

- Replies

- 2

- Views

- 209

- Replies

- 39

- Views

- 2K

- Replies

- 9

- Views

- 1K

- Replies

- 40

- Views

- 3K