Knowing the machine to be used would be handy.

A really big broach would be very fast and you could pop these out finished in less than 30 seconds each.

Tolerances on size and square also, just cleaned up, many thous, a few tenths, microns?

In a VMC or HMC some would consider it one op but multiple tools.

On a big manual mill is doing a few passes up front, moving back and doing a few more still one operation since it is only one clamp?

Part is of decent size, you may want to job it out to someone with machines and tooling on hand.

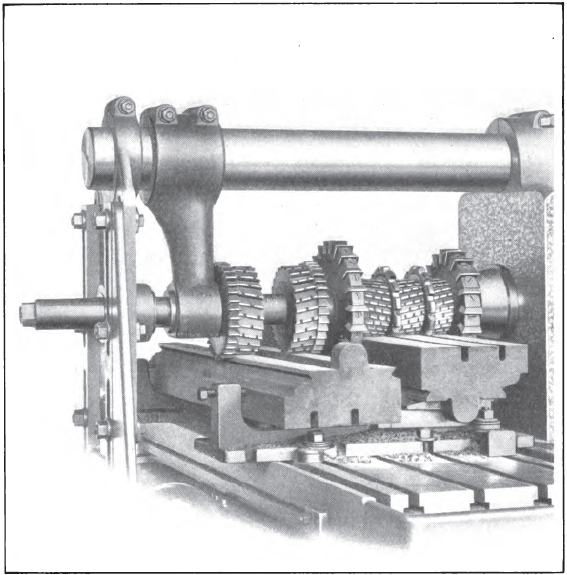

I wonder what it would cost to just tool up that horizontal above in today's dollars?

Somewhere volume comes into play as to best for the buck. On a 9x42 B-port it's two clamps but maybe cheaper.

Many ways to skin a cat, it can also be done a on a big surface grinder.

Bob

(I know all this not much help but the phrase "cast granite" always says something to me so tossing a penny in the pot for the OP whom I do wish well on this endeavor.)