athack

Stainless

- Joined

- Nov 2, 2009

- Location

- Michigan USA

Hello All,

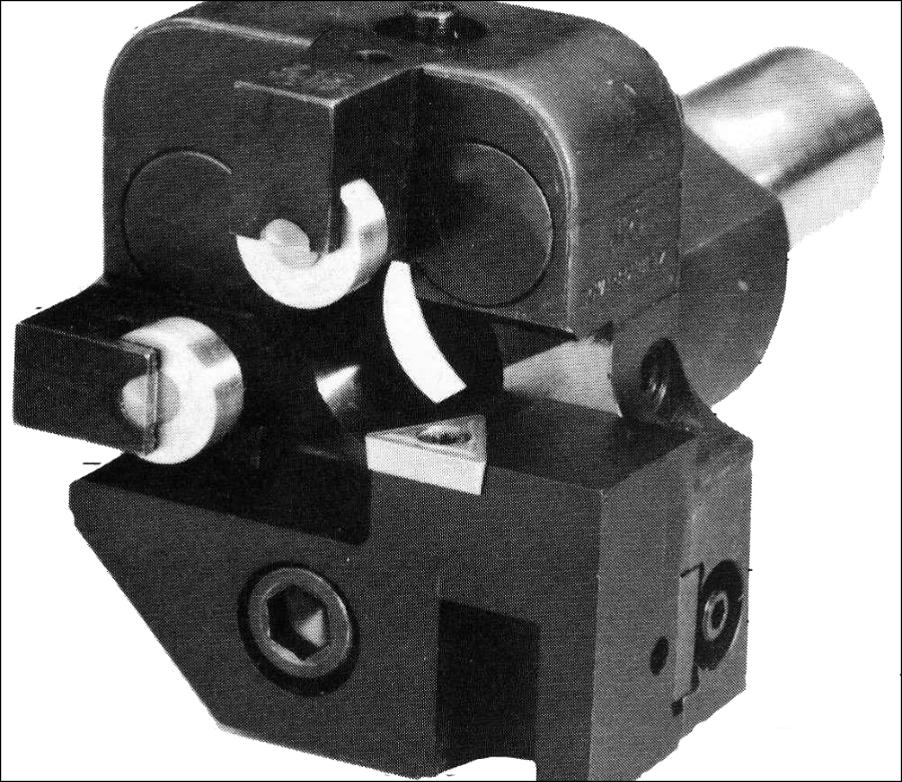

I am looking for a tool block or a adjusting sleeve or something of that nature that will let me adjust the centerline of the tools in a turret. I know about the old style Warner Swasey type that have 4 adjusting screw and locking screws. I would think that there most be something on the market to aid in this. Even after a teck has been here to re-align the machine things are just not right.

I have found this video. Nine9 Center Hight Adjust Sleeve - YouTube but can't seem to find a place to buy. There must be something already on the market.

Please help and Thank You!

I am looking for a tool block or a adjusting sleeve or something of that nature that will let me adjust the centerline of the tools in a turret. I know about the old style Warner Swasey type that have 4 adjusting screw and locking screws. I would think that there most be something on the market to aid in this. Even after a teck has been here to re-align the machine things are just not right.

I have found this video. Nine9 Center Hight Adjust Sleeve - YouTube but can't seem to find a place to buy. There must be something already on the market.

Please help and Thank You!