npolanosky

Cast Iron

- Joined

- Apr 9, 2016

- Location

- USA, FL

I acquired a '93 milltronics Partner 1F for real cheap a few months ago intending to use it as a second op machine. The previous owner just didn't have an interest in mill work anymore (transitioning to EDM work only) said it worked fine, just needed a limit switch replaced, so I figured that would be a super easy fix. It sits on my floor for a month while I find time to wire it up (and realize I need to buck the 250v from the power company down to 220v- took care of that).

Finally got it powered up, replace the supposed failed limit switch (which tested fine actually), and it still shows the same alarm as it did before- 450: Estop has been pressed or machine is on a limit switch. Interestingly though, I can press reset and it will work for about 1 minute before triggering again. The less time I give it before resetting, the less time it takes to alarm, ranging from instantaneous to long enough to home it, jog a bit, and do a tool change or two. Everything else seems to work perfect.

It'll alarm even if completely stationary and idle. I have checked the series-wired limit switches independently and also checked the entire string of them at the terminal block in the electrical cab- They don't indicate an open circuit and aren't intermittent. I ran a jumper across the entire set, from 6A (spindle fault) to 9 (Z limit IIRC). Still got an estop alarm, which rules out any broken wires or intermittent switches.

I can run the machine normally if I hold in the reset button (which keeps the latching enable relay hold on)

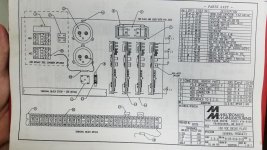

All I can figure is a component on a board, a bad relay, or a failing power supply. The electrical diagram is pretty simple, I'll attach it here shortly.

If anyone has an idea of what else to check, let me know. It seems like it has to be something simple tripping up the Estop alarm. Maybe thermal (overloaded/overheating linear power supply dropping out and then resetting?) or something attached to a capacitor, since the amount of time it will run is related to how long you wait before resetting it.

Milltronics support has been largely unresponsive (and I don't blame them, this machine is 25 years old and they haven't received a penny from me) so I'm hoping someone here has come across this issue before.

Pics and video of the issue incoming shortly.

Finally got it powered up, replace the supposed failed limit switch (which tested fine actually), and it still shows the same alarm as it did before- 450: Estop has been pressed or machine is on a limit switch. Interestingly though, I can press reset and it will work for about 1 minute before triggering again. The less time I give it before resetting, the less time it takes to alarm, ranging from instantaneous to long enough to home it, jog a bit, and do a tool change or two. Everything else seems to work perfect.

It'll alarm even if completely stationary and idle. I have checked the series-wired limit switches independently and also checked the entire string of them at the terminal block in the electrical cab- They don't indicate an open circuit and aren't intermittent. I ran a jumper across the entire set, from 6A (spindle fault) to 9 (Z limit IIRC). Still got an estop alarm, which rules out any broken wires or intermittent switches.

I can run the machine normally if I hold in the reset button (which keeps the latching enable relay hold on)

All I can figure is a component on a board, a bad relay, or a failing power supply. The electrical diagram is pretty simple, I'll attach it here shortly.

If anyone has an idea of what else to check, let me know. It seems like it has to be something simple tripping up the Estop alarm. Maybe thermal (overloaded/overheating linear power supply dropping out and then resetting?) or something attached to a capacitor, since the amount of time it will run is related to how long you wait before resetting it.

Milltronics support has been largely unresponsive (and I don't blame them, this machine is 25 years old and they haven't received a penny from me) so I'm hoping someone here has come across this issue before.

Pics and video of the issue incoming shortly.